Creating Consistency in Mixing and Feeding Milk Replacer

Click here to view as a pdf: Creating Consistency in Mixing Milk Replacer

By Ryan Leiterman, D.V.M.

By Ryan Leiterman, D.V.M.

Director of Technical Services

Mixing milk replacer to feed pre-weaned calves is a daily task on many farms. And it’s a simple task, right? All it takes is adding the correct amount of powdered milk replacer to the correct amount of water, how hard can that be? While mixing milk replacer may seem easy, mixing milk replacer correctly and consistently for every single feeding is a much more difficult task.

Why is Accurate Mixing Important?

Feeding calves a milk replacer solution with the same concentration of total solids for every feeding is important because it impacts calf health and performance. Research has shown that calves receiving milk replacer solutions with varying concentrations are more susceptible to diarrhea, clostridial bloat and respiratory disease, as well as reduced average daily gains.

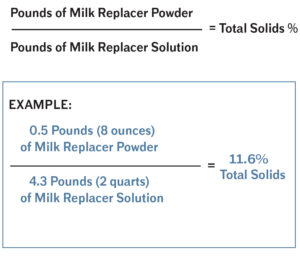

Most milk replacer tags give instructions for an 11.6% total solids mixture. If you mix 8 ounces of powder into 1.8 quarts of water to make 2 quarts of milk replacer solution, that is an 11.6% solids solution. We know that finished milk replacer solution weighs roughly 8.6 pounds per gallon. The formula to calculate the percent total solids for a milk replacer solution is:

Calves have a narrow window of total solids concentration that they can tolerate. A total solids concentration that is too high, or too low, can lead to diseases like diarrhea and clostridial bloat. Most milk replacer manufacturers recommend that calves be fed a milk replacer solution mixture between 11.5%-13.0% total solids.

How is Accurate Mixing Defined?

An accurately mixed milk replacer solution will have a 0.5% plus or minus deviation from the exact target solution concentration. For example, if you are targeting a 12.5% total solids concentration then samples ranging from 12.0%-13.0% total solids are considered accurately mixed.

How Can You Monitor Total Solids Concentrations in Mixed Milk Replacer?

Many farms use a Brix refractometer for colostrum management. This same refractometer can be used to monitor milk replacer total solids concentrations. Each milk replacer is different, and every company should have a unique formula to convert a % Brix reading into a percentage of total solids. For the Crystal Creek® Swift Start® calf milk replacer, the total solids percentage of the milk replacer solution can be calculated by using a Brix refractometer with the following equation:

Tips to Ensure Accuracy and Consistency in Calf Milk Replacer Mixing

Weigh the milk replacer powder with a scale, not the scoop provided in the bag.

Milk replacer powder density is different throughout the bag, with the least dense powder being on the top of the bag and the denser powder being on the bottom of the bag. The amount of powder contained in each scoop is different and subsequently can lead to significant total solid percentage variations within feedings. What one person vs. another, calls a full scoop can be quite different.

For a fun experiment have everyone on the farm that is feeding calves get together and fill a scoop with the amount of milk replacer powder they normally use to feed a calf. Weigh all the scoops to see how similar (or different) they are. The results may be surprising!

Calibrate the mixing container for water volume. Accurately measure out water volume and make marks inside the mixing container to ensure quick and accurate water measurements for future mixing batches. Add ½ the volume of water to the mixing container, then weigh and add the milk replacer powder. Mix the powder into a smooth solution and then fill the container to the pre-measured water volume mark.

Measure the water temperature during mixing. Mix milk replacer powder in water with temperatures ranging from 110° F to 120° F to ensure proper fat and protein dispersion within the solution.

Measure the milk replacer solution temperature prior to feeding.

Deliver milk replacer to the calves at a milk temperature that ranges from 101° F – 105° F. Milk replacer that is fed at a temperature cooler than 101° F can negatively impact the health of the calves and increase the risk of scours, bloat and reduced digestibility. Remember to measure the milk replacer temperature being fed to the first, middle and last calf for an accurate representation of milk temperatures.

Use a Brix refractometer to check that the milk replacer solution is being mixed to the proper total solids concentration at least weekly.

Crystal Creek® Swift Start® Calf Milk Replacer % Total Solids = (1.128 x % Brix) + 0.291

Make sure all mixing and feeding equipment is properly cleaned and disinfected.

Biofilms are one of a calf raiser’s worst enemies. Crystal Creek® offers a full line of cleaning and disinfecting products that are effective on a broad spectrum of pathogens known to harm calf health.

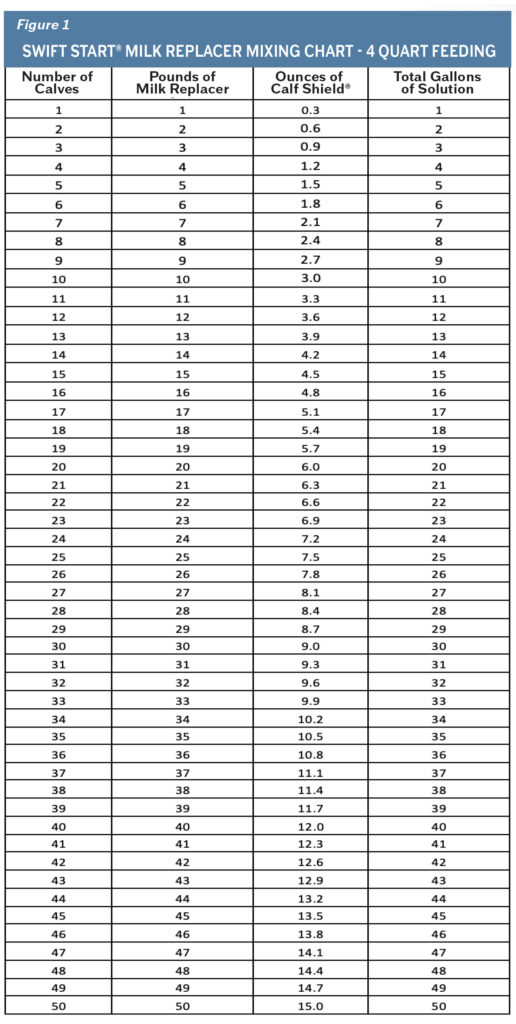

PRO TIP: each pound of milk replacer powder makes one gallon of finished solution (yielding an 11.6% total solids) so if 6 pounds of powder is being used, there should be exactly 6 gallons of milk replacer solution once done mixing. Figure 1 shows the Swift Start® Calf Milk Replacer mixing chart; a quick reference to use for what amount of milk replacer is needed for the given number of calves being fed. If you are adding Calf Shield® to milk replacer, that inclusion rate has been provided in the chart as well.

Accurately and consistently mixing milk replacer is important and has a direct impact on calf health. Weighing milk replacer powder is more accurate, and less prone to variations, than using scoops or containers to measure milk replacer powder. Creating and enforcing consistent milk replacer mixing protocols can help improve overall calf performance.

References available upon request.