Click here to view as a pdf: Four Air Exchanges Per Hour: A History Of Calf Barn Ventilation And An Industry That Is Slow To Change

By Ryan Leiterman, D.V.M

By Ryan Leiterman, D.V.M

Director of Technical Services

When discussing calf barn ventilation, invariably the topic of using four air exchanges per hour for cold weather ventilation will come up. After all, we wouldn’t want “too much” of that cold air in the barn. Or would we? Who came up with the idea to use four air exchanges per hour during cold weather and why? To understand our industry’s current ventilation recommendations, we must first understand the history of calf barn ventilation research.

Take a trip back in time. It’s the late 1970’s and Jimmy Carter is president. A new F-150 pickup truck sells for $5,4891 and US milk production averages 11,891 pounds per cow per lactation2.

Over the winter of 1977, the University of Minnesota conducted a research trial evaluating calf respiratory health by comparing two different ventilation rates; one air exchange per hour vs four air exchanges per hour. One group of 40 Holstein bull calves received a ventilation rate of one air exchange per hour while another group of 40 Holstein bull calves received a ventilation rate of four air exchanges per hour. All other variables were kept constant between the groups of calves. At the end of the trial, calves from each group were euthanized and their lungs were examined. The study concluded that the calves raised with four air exchanges per hour had fewer cases of pneumonia when compared to calves raised with one air exchange per hour.

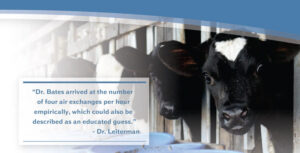

In 1979, Dr. Bates, a professor at the University of Minnesota published the 1977 trial results in a paper titled “Calculation of Ventilation Needs for Confined Cattle” in which he stated, “For air purity, the fundamental criterion in designing a calf barn ventilation system is to provide continuous exhaust at a minimal rate of about 4 air changes per hour. This will reduce aerosol contaminates in addition to controlling moisture.”

Note that Dr. Bates refers to four air changes per hour as a minimal air exchange rate, suggesting that higher ventilation rates may be necessary.

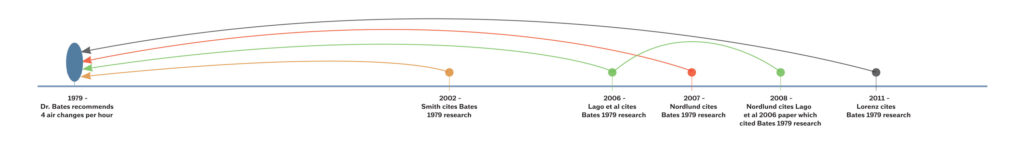

Nearly every scholarly publication regarding calf barn ventilation in the past 20 years recommends four air changes per hour during cold weather, citing the paper of Dr. Bates in 1979. To date, peer reviewed research exploring cold weather ventilation rates greater than four air changes per hour has not been conducted.

In 2002, Dr. Bradford Smith released the third edition of “Large Animal Internal Medicine”, where he states that mechanically ventilated barns should have a “fan capacity to achieve 4 air changes per hour in winter.” and provides the paper written by Bates in 1979 as the citation for that recommendation.

In 2006, Dr. Lago published a paper titled “Calf Respiratory Disease and Pen Microenvironments in Naturally Ventilated Calf Barns in Winter “, where he discussed the differing recommendations for minimal ventilation rates of calf barns and cites the 1979 paper of Dr. Bates.

In 2007, Dr. Ken Nordlund published a paper titled “Housing Factors to Optimize Respiratory Health of Calves in Naturally Ventilated Calf Barns in Winter“, where he cites the 1979 work of Dr. Bates stating that cold weather ventilation systems should be used to “direct small volumes of fresh air into the pens.”

In 2008, Dr. Ken Nordlund published a paper titled “Practical Considerations for Ventilating Calf Barns in Winter”, where he cites the 1979 work of Dr. Bates, stating “Current recommendations for minimal winter ventilation rates in calf barns range from 15 cubic feet per minute to four air changes of the building per hour.”

In 2011, Ingrid Lorenz cites the 1979 work of Dr. Bates in a paper titled “Calf Health from Birth to Weaning III. Housing and Management of Calf Pneumonia”, where she states: “To prevent adverse conditions, at least 4 air changes per hour are needed in winter.”

Why is the dairy industry still using calf barn ventilation recommendations that are based on a single research trial done in 1977?

The simple answer is change happens slowly. The real reason for a lack of change has more to do with human nature than it does with ventilation technology. A population of people is comprised of five distinct groups and an idea or innovation must be widely adopted over time in order to self-sustain3. The five groups are:

1) Innovators: Visionaries and inventors that develop new ideas.

2) Early Adopters: People who are first to try new ideas. They jump at new products, embrace change and love being the first in their social group to do something new.

3) Early Majority: People who don’t want to try something until their neighbors have tried it first.

4) Late Majority: People who don’t want to try something new until the majority of other people are already doing it. These people want to be sure that it is a good idea. They do not love change but they are willing to adapt.

5) Laggards: People who are resistant to, or refuse, change3.

Once an idea obtains acceptance from the Early Majority group it acts like a tipping point and the Late Majority and Laggards will soon follow until the idea or innovation is widely accepted. For change to happen, a new idea must go through the same process of acceptance throughout the population in order to replace the old idea. The idea of using four air exchanges per hour for winter ventilation has been with our industry for a long time. When it first came out, the innovator, Bates, faced challenges in getting his idea to take hold. Now that the Bates idea has gone through the various stages of acceptance, it has become widely adopted.

What’s Next?

Before the dairy industry can advance the topic of calf barn ventilation forward, we must first realize that the recommendation of Bates in his 1979 paper was that four air exchanges per hour in the winter should be viewed as a minimum ventilation rate.

There is a common belief in the dairy industry that if we bring “too much” fresh air into the barn, it will create a draft on the calves; but this is not true. Using modern ventilation methods, it is quite easy to achieve higher ventilation rates without causing a draft. Furthermore, calves raised outdoors in hutches have significantly lower respiratory disease rates than their barn raised counterparts4; showing us that in the absence of a draft, there is no such thing as “too much” fresh air.

Four air exchanges per hour has been proven to be better for calf health than one air exchange per hour. So, shouldn’t we as an industry be curious if six, eight or maybe even ten air exchanges per hour would be better than four? Some of the innovators and early adopters in our industry are already using winter ventilation rates greater than four air exchanges per hour and seeing positive results.

The industry needs new, innovative research that compares air quality and calf health with cold weather ventilation rates greater than four air changes per hour.

Numerous improvements in calf housing and welfare have been made over the last four decades but the industry still suffers from calfhood pneumonia. Until the day comes that calves in barns have the same, or less, respiratory disease rates as calves housed in outdoor hutches, the work on improving calf barn ventilation is not finished.

The first step of change is innovation and innovation can only be driven by curiosity. We, as an industry, need to be curious and start to wonder if four air changes per hour is the best option for calves. New and updated research is needed.

SOURCES:

-

Retrieved from thedrive.com at https://www.thedrive.com/news/9942/check-out-this-cool-infographic-of-ford-f-150-prices-over-the-years

-

Retrieved from USDA Economic Research Service https://www.ers.usda.gov/webdocs/publications/45868/17034_err47b_1_.pdf?v=41746

-

Rogers, Everett (1962), “Diffusion of Innovations”.

-

Lance et al., (1992); Losinger & Heinrichs, (1997), and Retrieved from Irish Veterinary Journal at https://irishvetjournal.biomedcentral.com/articles/10.1186/2046-0481-64-14

This article was originally published in the Progressive Dairy Magazine at https://www.progressivedairy.com/topics/calves-heifers/4-air-exchanges-per-hour-a-history-of-calf-barn-ventilation-and-an-industry-that-is-slow-to-change