Increasing Herd Profitability Despite Low Milk Prices

Click here to view as a pdf: Increasing Profitability Despite Low Milk Prices

By Teresa Marker, B.S.

Milk prices fluctuate due to market supply and demand. When milk prices are low, producers find themselves evaluating their current herd status and profitability. Many producers start looking at ways to improve herd health or try to cut costs by eliminating additives. One farm in northwestern Wisconsin, which milks 160 Holstein cows in a robot barn, decided it was time to look for a company that could help improve their situation. A neighbor of theirs, that is currently a Crystal Creek® client utilizing our Crystal Creek® Dairy Nutrition Model (CCDNM), referred them to Crystal Creek®. Their previous nutritionist was using a “band-aid” approach with the herd and it wasn’t working.

The herd owners and their sons stated they had three goals they would like to accomplish with their herd:

- Improve Cow Robustness

- Increase Milk Production

- Increase Profitability

These are all very sustainable and achievable goals. In order to achieve these goals, I consulted our staff veterinarian, Dr. Ryan Leiterman, to help address and review current herd health protocols. As a team, we sat down to discuss a strategy moving forward by focusing on the transition cows, improving nutrition and understanding the value of timely communication with each other.

Step #1: Focus On Transition Cows

Prior to switching to the CCDNM, this herd fed the same ration to all of the lactating cows. There are three robots being utilized for milking. Two robots milk in a pen of 120 cows and another robot is dedicated to a pen of 60 cows. The larger group had access to headlocks, but the smaller group of 60 cows did not. All dry cows were fed the same ration and cows were moved to maternity pens a few days prior to calving. To improve the overall transition, we looked at bottlenecks that may be limiting dry matter intake prior to and after freshening. One suggestion Dr. Ryan made was to keep close-up cows out of the maternity pen until just prior to freshening. This limits a stressful pen move for the dry cows that could possibly decrease their dry matter intake. Another suggestion was to install headlocks in the milk cow barn for the group of 60. All fresh and early lactation cows could be moved into that 60 stall pen with plenty of bunk space. The new headlocks not only reduce competition at the feed bunk, but allow this producer to lock up his fresh cows several times per week to monitor and treat common fresh cow conditions (i.e. ketosis, milk fever, uterine infections and udder health). Dr. Ryan created a “Fresh Cow Protocol” for this herd that helps them be more proactive in their observation and treatment of their fresh cows.

Step #2: Improve Nutrition

One of the goals of the CCDNM is to improve overall rumen function and fiber digestion. I evaluated both the milk and dry cow rations and put together a step-by-step strategy that would eliminate the possibility of a milk production decrease during the transition. Items removed during the transition included a previous mediocre mineral source, an energy booster product, Crystalyx® Lick Tubs and distillers’ grains. Items added to the ration included Crystal Creek® mineral, liquid molasses and free choice mineral/salt. Dry matter intake was maintained and adjusted as cows were separated into a Fresh Cow Group and Later Lactation Cow Group. Rations were adjusted each week to focus more on fiber and less on supplemental protein and grain. During one visit, I noticed red mold on some corn in the TMR. We pulled a TMR sample to screen for mycotoxins. This test came back positive for a significant amount of vomitoxin. To determine all of the sources, we tested the high moisture corn and corn silage being added to the ration. It turned out that one of the corn silages (they had two open bags) and one of the high moisture corn sources (they were feeding from two silos) were the culprits. The clean sources of corn were dedicated to the dry and fresh cows and the later lactating cows were fed the corn and silage that contained the vomitoxin. Crystal Creek® Fuse 207 was added to the dry and fresh cow groups as a precaution against mycotoxins. Crystal Creek ® Fuse 207 and Mycotex were added to the later lactating cow group to address the vomitoxin. Finding toxins in the feed can be a significant challenge to any dairy herd. This herd had been exposed to a significant level of mycotoxins without a proper mycotoxin binder for a minimum of 4 months.

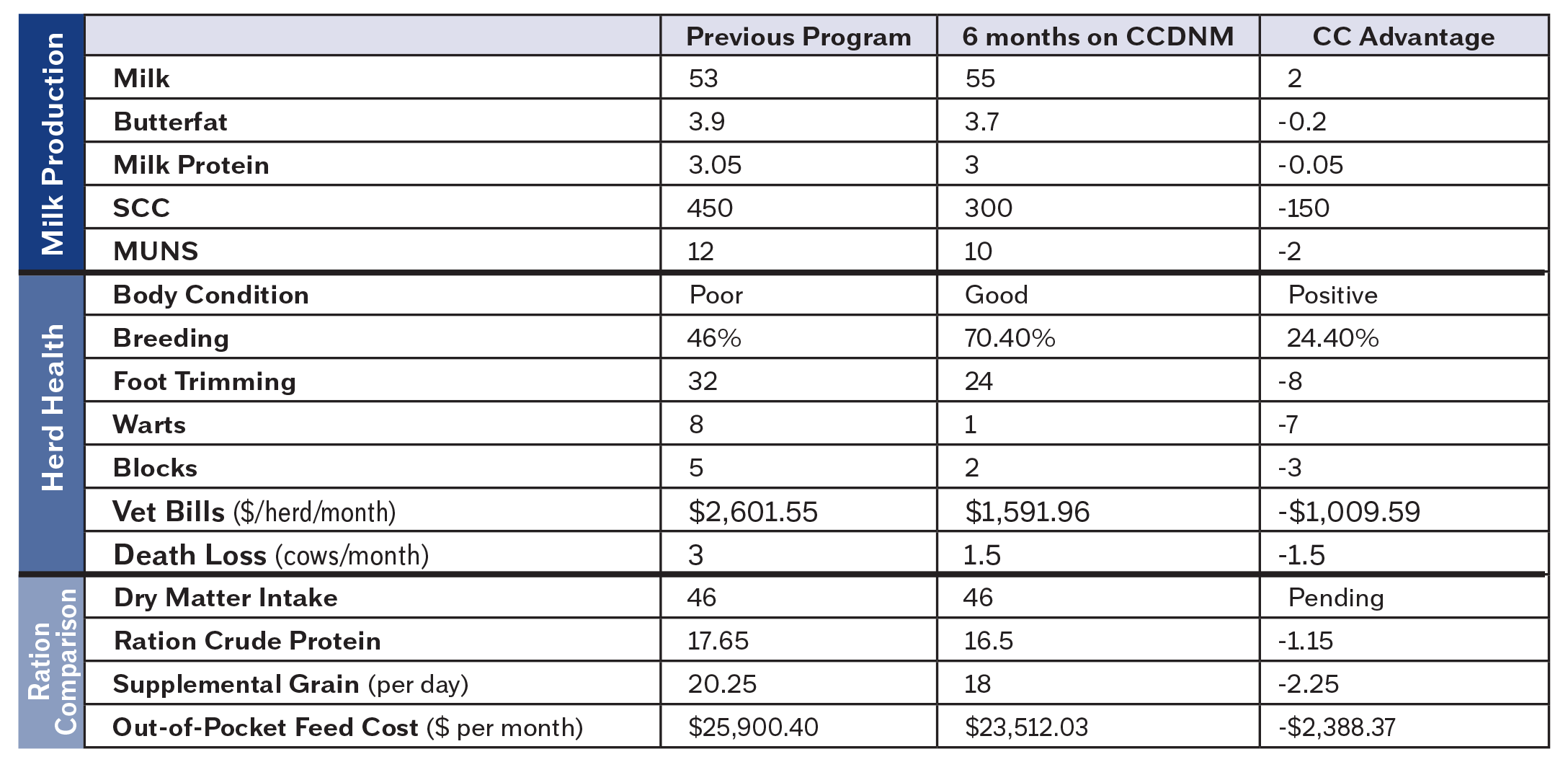

Step #3: Observation And Communication

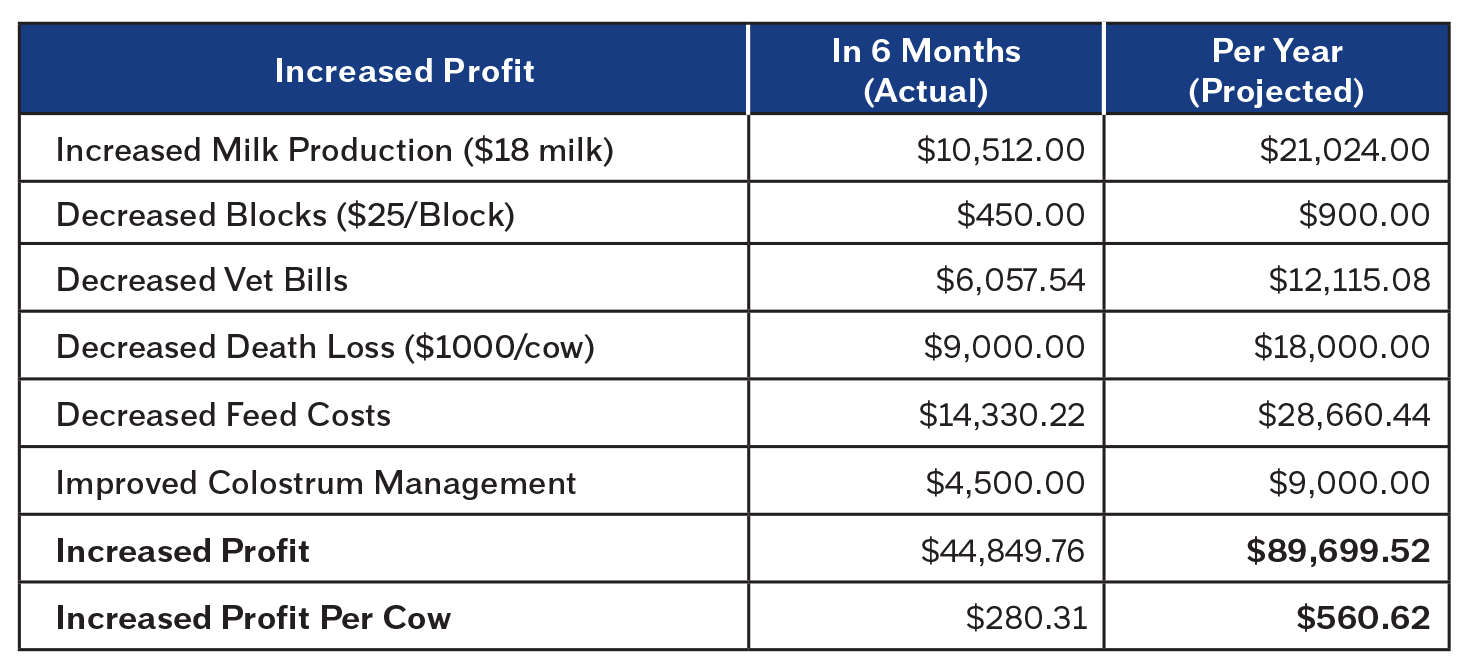

No team can be successful without proper communication. These producers are great communicators and their willingness to provide information and feedback has played a huge part in their success. If the cow manure consistency or dry matter intake changed, they called so the ration could be adjusted. Rations were sometimes adjusted three times per week, depending on how the cows were responding. These producers are also very proactive on taking forage samples so that the ration can be as accurate as possible. Any fresh cow questions were directed to Dr. Leiterman and treatment protocols were adjusted as necessary. Each communication by the producer that resulted in a change or adjustment to the herd was documented, as were the subsequent changes in the herd’s performance. After the first 6 months we sat down together as a team to evaluate where we were, what we did and what the plan was for the future. The charts included in this article show the results of this herd after just six months on the CCDNM. Looking at our initial goals, we were successful in achieving them. Our goals for the future are improving milk production and profitability by maintaining focus on the fresh cows, improving breeding and decreasing days in milk.

Small changes to a herd can yield big results. An increase in profitability by $89,699.52 per year ($560.62/cow/year) is nothing to overlook. Milk production is starting to increase and the herd is now positioned well for even higher profitability in the future. Most of this herd’s profit came from reduced feed costs, improved nutrition and better transition cow management. If you are interested in learning more about the Crystal Creek Dairy Nutrition Model, please contact one of our nutritionists at 1-888-376-6777. There is no cost to call!