Crystal Creek® is proud to present Jessica Getschel and Dr. Ryan Leiterman’s recent article published in the Progressive Dairyman Magazine.

Progressive Dairyman will be featuring three of Jessica Getschel’s articles on calf barn ventilation this year. Jessica is a livestock nutritionist and ventilation specialist at Crystal Creek® and holds a bachelor of science degree from University Wisconsin Madison in Dairy Science and Microbiology.

ARTICLE #1

Key Design Features To Consider Before Building A New Calf Barn

Click here to view as a pdf: Key design features to consider before building a new calf barn

By Jessica Getschel, B.S.

Proper barn planning saves time and money. For every decision, it is important to understand its associated ramifications. In calf barns, housing style and pen configuration decisions impact ventilation options, which in turn affects the overall success of the barn. Before building a calf barn, think about the ventilation requirements for every season. Allocate at least 10 percent of the overall building cost for the purchase of a well thought out ventilation system and ask these three questions as you consider your ventilation options:

- Will the system deliver a consistent source of fresh air into the barn during all seasons?

- Will the system effectively control the airspeed at calf level?

- Can the ventilation system rapidly adjust to the changing weather conditions of spring and fall when there are warm days and cool nights?

Housing style impacts ventilation choices

Ventilation options vary according to the calf housing style. Group-housed and individually-penned calf barns face different limitations when it comes to providing good air quality. These limitations need to be addressed while considering the three routes of ventilation: natural, mechanical, or a hybrid of the two. Decades of past experience show that natural ventilation alone does not perform well without mechanical support. For that reason, most barns today are ventilated either strictly mechanically or naturally with mechanical assistance.

Group pens typically have very open spaces with little obstruction to airflow. This allows air to be delivered to the calf at their level from any direction. The concept of an open area broadens ventilation options. Fresh air can be drawn from open curtains and panel fans can increase the speed of the fresh air during warm weather to help with heat abatement. Both positive pressure tube ventilation and tunnel ventilation can be designed to provide seasonally appropriate airflow. The key to successfully ventilating group housing is ensuring that there are no solid barriers in the path between the fresh air inlet and the calves. Keep in mind that group pens pose a larger risk of contagious pneumonia spread by nose to nose contact. As a result, it is possible to have increased respiratory disease rates in group-housed calves, despite excellent air quality inside the pens.

Individual pens typically have solid sidewalls which obstruct airflow at the calf level. Air must be directed into the pen from above the calf or through the back of the pen if an open material such as a cattle panel is used. When designing a ventilation system for individual pens, it is important to recognize that the air quality above and around the pens does not accurately reflect the air quality of the calf’s immediate pen space. It is quite challenging to direct fresh air into the calf’s small, obstructed area and as a result, many ventilation systems today do not provide individual pens with the necessary air volume changes. Tunnel ventilation systems may deliver fresh air to the barn, but may not effectively deliver fresh air to the calf level. Similarly, panel fans move air over the top of pens but do not effectively deliver fresh air at the calf level. Positive pressure tube ventilation is arguably the best way to ventilate individual pens, as the tubes can uniformly distribute fresh air down the length of the barn and direct it straight into the pens. Since the fresh air comes from directly above, the solid walls of the pen no longer pose as obstacles. With individual pens, the layout should be designed to start two to three feet from the outside walls. This arrangement will help prevent drafts from the sidewall curtains, facilitate bedding delivery and avoid straw contamination of the milk and grain buckets.

Individual pens typically have solid sidewalls which obstruct airflow at the calf level. Air must be directed into the pen from above the calf or through the back of the pen if an open material such as a cattle panel is used. When designing a ventilation system for individual pens, it is important to recognize that the air quality above and around the pens does not accurately reflect the air quality of the calf’s immediate pen space. It is quite challenging to direct fresh air into the calf’s small, obstructed area and as a result, many ventilation systems today do not provide individual pens with the necessary air volume changes. Tunnel ventilation systems may deliver fresh air to the barn, but may not effectively deliver fresh air to the calf level. Similarly, panel fans move air over the top of pens but do not effectively deliver fresh air at the calf level. Positive pressure tube ventilation is arguably the best way to ventilate individual pens, as the tubes can uniformly distribute fresh air down the length of the barn and direct it straight into the pens. Since the fresh air comes from directly above, the solid walls of the pen no longer pose as obstacles. With individual pens, the layout should be designed to start two to three feet from the outside walls. This arrangement will help prevent drafts from the sidewall curtains, facilitate bedding delivery and avoid straw contamination of the milk and grain buckets.

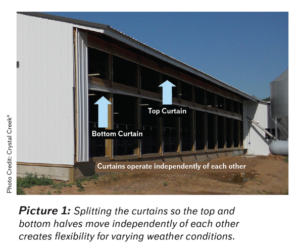

Whether or not sidewall curtains will benefit your ventilation plan is another option to consider when designing a calf barn. Sidewall curtains offer a great way to naturally ventilate calf barns, with many different arrangements to consider from the height of where the curtain starts to the direction which it rolls. Rolling curtains from the bottom up allows fresh air to enter at the calf level. It can also keep natural gusts of air from interrupting air streams directed out of positive pressure tubes.

Imagine in the spring or fall, when top-down curtains are open at the top for some extra fresh air. Unfortunately, the air coming through the cracked curtain will flow high above calf level and will likely disrupt the streams of fresh air coming out of the positive pressure tube. This scenario not only fails to provide fresh air at the calf level, it also limits the effectiveness of the assisting mechanical ventilation.

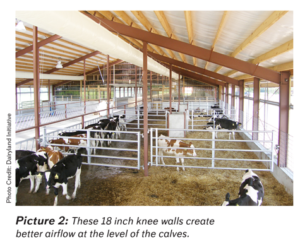

In addition to determining the height and direction of the roll of the sidewall curtain, the height of the concrete knee wall must also be determined. Historically, naturally ventilated barn blueprints required four-foot tall concrete knee walls, upon which fabric curtains were installed. Tall knee walls interfere significantly with natural ventilation because they create a wind shadow that leaves large stagnant air spots around the perimeter of the building.

Bedding type and frequency of clean out need to be considered when determining concrete knee wall height. The height of the knee wall must be tall enough that bedding does not build up over the height of the wall or spill over to the outside when cleaning out the pens.

Floor Plan Layout

Besides ventilation and housing style considerations, the floor plan layout needs to address issues such as drainage and feed delivery. When considering a new facility, under the bed drainage is often used. A pre-weaned calf will generate roughly one gallon of liquid waste every day. Placing a drain under the bed space of the calves has been shown to help keep bedding dry and make a more comfortable calf environment (Picture 3a).

This concept applies to both bedded pack and individual pen barns. Aggressive concrete slopes of one inch per foot are used to rapidly move liquid wastes to a centrally located concrete trench that contains a drain tile covered by pea gravel and two-inch rock (Pictures 3b). The drain tile removes the liquid waste from the barn and moves it to a holding tank. Visit the Dairyland Initiative website:

This concept applies to both bedded pack and individual pen barns. Aggressive concrete slopes of one inch per foot are used to rapidly move liquid wastes to a centrally located concrete trench that contains a drain tile covered by pea gravel and two-inch rock (Pictures 3b). The drain tile removes the liquid waste from the barn and moves it to a holding tank. Visit the Dairyland Initiative website:

https://thedairylandinitiative.vetmed.wisc.edu/home/housing-module/replacement-housing/key-features-for-all-calf-barns/ for information on the most current building ideas and techniques.

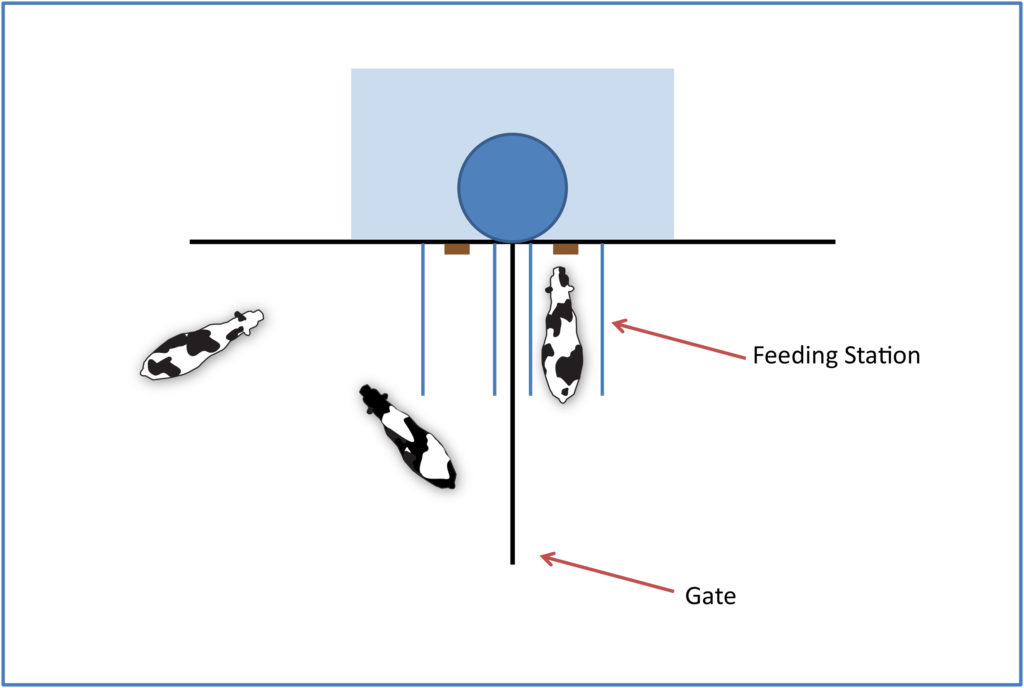

In an open housing situation, automatic calf feeders are most commonly used. Competition at the feed bunk is a common occurrence in adult cow housing and as an industry, we take steps to minimize its negative effects. Likewise, feed bunk competition in group-housed calves can negatively affect their performance. The auto-feeder nipples on automatic calf feeders are small, discrete points that must be shared by a number of calves; further exacerbating the competition. It is extremely important that feeding points are easily accessible to increase the chances that smaller, or less aggressive, calves feel comfortable approaching the feeding station.

How the feeding station is placed within the pen can make a dramatic impact on its accessibility.

Locating the feeding station along a wall or gate eliminates access from that side, leaving only one side available to approach the station. This configuration will limit access for timid calves (Picture 4a).

Locate the feeding station in the middle of a pen, away from gates or obstructions. This will allow access from all sides and improve access for timid calves (Picture 4b).

With proper planning, the investment of building a new calf barn can pave the way for years to come with sizeable returns in calf health, performance, and eventually milk production. Air quality and calf comfort are critical factors that can influence the success of any calf barn. Seek out professional industry consultants to help you plan your barn before pouring the concrete. Your calves and your checkbook will thank you.

This article was originally published with the Progressive Dairyman Magazine at:

ARTICLE #2

Understanding The Principles Of Calf Barn Ventilation

Click here to view as a pdf: Understanding the principles of calf barn ventilation

By Jessica Getschel, B.S.

Understanding the basic principles of calf barn ventilation is essential in evaluating the many different ventilation options available today. There is no single ventilation system that will work for every situation because each calf barn is unique in its structure and layout.

The goal of a properly designed ventilation system should be to provide clean, fresh air at all times for healthy calf development. Ventilation is responsible for removing accumulated heat, moisture, airborne pathogens and noxious gases from the animal’s environment. These factors support the rationale behind ventilating year round, as moisture, pathogens, and gases are constantly being released and a buildup of these factors leads to respiratory stress in calves.

Properly managing the following three basic principles of calf barn ventilation can ensure the best air quality possible for your calves:

- Fresh air volume

- Airspeed at calf level

- Fresh air distribution

Fresh air volume

The amount of fresh air entering the barn is called volume. Fresh air is introduced into a barn to remove and dilute accumulated heat, humidity, airborne pathogens and noxious gases. As the level of these air contaminants increases so does the need for a greater volume of fresh air to achieve proper air quality. The rapidity at which this volume of fresh air is introduced into the barn determines the air exchange rate.

The length of time it takes for the complete volume of air contained in the barn to turn over once is called one air exchange. The recommended frequency of air exchanges will vary based upon the season.

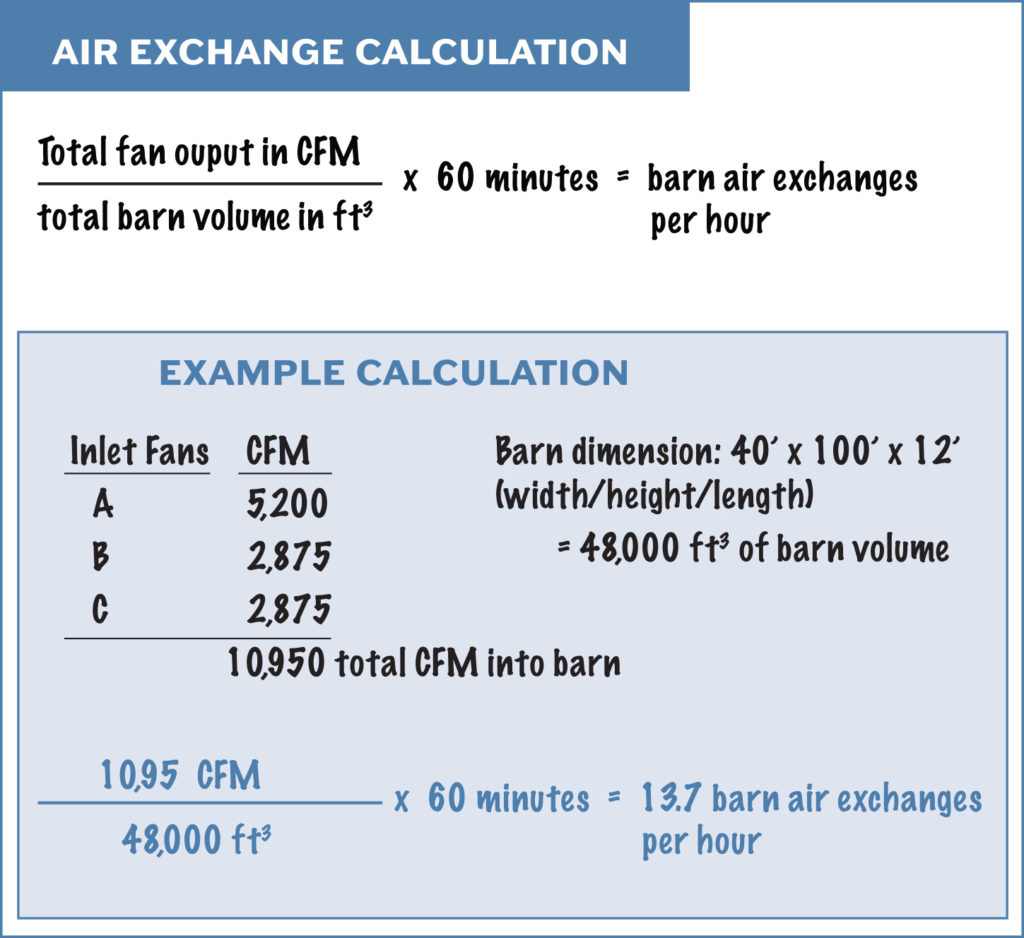

In mechanically ventilated calf barns, the volume brought into the barn can be calculated by the fan output. Fan output is measured at a rate of cubic feet per minute. Adding the cubic feet per minute of every fan that draws fresh air into the barn will yield the total volume of fresh air coming into the barn per minute. It is necessary to know both the volume of fresh air coming in per minute and the total volume of the barn in order to calculate the total barn air exchanges (see Figure 1).

Fans that are not directly tied to a source of fresh air, such as panel or basket fans, are considered recirculation fans. These fans are great at increasing air speeds and can help with heat abatement in the summer, but should not be counted when calculating the fresh air volume coming into the barn.

According to the University of Wisconsin School of Veterinary Medicine, properly ventilated calf barns should be experiencing four air exchanges in the winter, 10 to 20 air exchanges in the spring and fall, and 40 air exchanges in the summer.

The University of Wisconsin School of Veterinary Medicine also has volume recommendations based on calf stocking density. In the winter, they recommend 15 to 30 cubic feet per minute (cfm) of fresh air per calf. Unfortunately, in barns utilizing natural ventilation, there is no way to precisely quantify the volume of air brought into the barn due to inconsistent weather patterns and wind speeds.

Airspeed at calf level

Airspeed is the measure of how fast the air is reaching the calves. Similar to air volume requirements, airspeed recommendations change according to the season. It is important to evaluate how air speeds change throughout the year, as the rapid air that is necessary for heat abatement in the summer can cause a harmful draft in the winter. During cold weather, calves should not experience airspeeds greater than 60 feet per minute. Summertime airspeeds are less strictly guided, but experience shows that air speeds of 200 feet per minute or greater are necessary for heat abatement.

The hottest days often have little breeze and can cause heat stress. Opening the curtains in a naturally ventilated curtain sidewall barn is a great way to allow airflow. However, because this system relies on natural breezes, which can be erratic, these systems cannot provide the consistent air speeds found with mechanical fans.

Fresh air distribution

Air distribution describes where the fresh air is delivered throughout the barn. The most important aspect of fresh air distribution is a uniform delivery of fresh air throughout the barn at calf level. Many ventilation systems meet air volume and speed requirements but fail to deliver fresh air at the calf level due to obstructions in the barn. Airflow follows the path of least resistance, and an obstruction, such as a tall concrete knee wall or solid pen panel, can deflect air away from its intended target: your calves.

There are several techniques that can help direct air to the calf. Some ventilation systems operate with baffles in an effort to create obstructions above the calf, forcing the air to be redirected down to the calf level. Systems with positive pressure tubes can dictate the direction of fresh air by the location of the holes in the tube. Some calf raisers extend a box off the exhaust fan that reaches to calf height, pulling air directly from the calf environment (see Figure 2).

A plywood box placed over an exhaust fan will remove the bottom 3 to 4 feet of dirty air from the barn while also encouraging the fresh air from the positive pressure tube to flow down and through the calf level. When attaching a box to a fan, provide two square feet of inlet area for every 1,000 cfm to avoid reducing the fan’s output.

Winter is the most difficult season to tell if fresh air is being distributed at the calf level, as a properly installed ventilation system should not show any visible signs of air movement, such as moving straw. To better assess airflow in the barn during winter, producers can use a fogging test as a visual tool (see Figure 3). Introducing fog next to the intake of an outside fan will demonstrate the path outside air takes once it enters the barn. Producers can also introduce fog in the center of a barn to see where it exhausts and how quickly it disperses. The goal is to exhaust all fog within 15 minutes or less from the time it enters the barn. This test can also help identify areas of still air, known as dead spots.

A well-designed ventilation system that employs proper air volume, speed and distribution will benefit calf health by improving air quality. It will do this through the removal of accumulated heat, humidity, airborne pathogens and noxious gases. Understanding the principles behind calf barn ventilation will allow producers to critically evaluate the ventilation options available and ultimately enable them to provide the best air quality for their calves.

This article was originally published with the Progressive Dairyman Magazine at:

and published with the Dairyman Canada Edition on Progressive Dairyman Magazine at:

ARTICLE #3

Ventilating A Retrofitted Stanchion Barn For Calves

Click here to view as a pdf: Ventilating A Retrofitted Stanchion Barn For Calves

By Jessica Getschel, B.S.

There’s nothing more picturesque than a dairy farm with a big red barn on a cobblestone foundation. Many of these barns, referred to as stanchion, tie stall or bank barns, were built decades ago and tell the story of a family that has been dairy farming for generations.

Over the years, many farmers have moved out of these older barns and into modern free stall barns for a variety of reasons; expanding herd size, new cow comfort recommendations or a new milking system to name a few. This departure leaves a vacant building that is prized for its emotional value to the farm. Rather than demolishing the barn or leaving it to harbor cobwebs, many dairy producers are choosing to put this space to good use: housing their calves.

An old stanchion barn is an excellent space for calf housing. It is an existing structure that is more affordable to retrofit than building a new facility. It provides a covered space that already has electricity and water available. The milk room attached to the barn that previously housed a bulk tank and milking equipment can easily be converted to a milk preparation room. This space can also be effectively utilized for cleaning and sanitizing feeding equipment.

For the sake of calf health, ventilation and the factors that impact it should be carefully considered before placing young calves in an old dairy barn. These barns tend to have very little opportunity for natural ventilation and rely considerably on mechanical ventilation. If the mechanical ventilation is not appropriately modified for calf housing, air quality will plummet as moisture and gases build up. Poor air quality will be detrimental to calf health and can significantly outweigh any benefits that may be gained from indoor housing.

Many stanchion barns come equipped with existing tunnel ventilation or a similar negative pressure system. Utilizing the barn’s existing ventilation can help you avoid additional remodeling costs, but it may also lead you to assume the calves’ ventilation requirements are met. Chances are, they are not. Producers should evaluate air speeds and perform a fogging test to determine if the current ventilation is appropriate for the calves and their location in the barn before populating it with calves.

Before committing to a ventilation plan, consider if the calves will be housed in group pens or individually. Group-housed calf pens are much easier to ventilate due to the openness of the space. For group housing, position the calf pens directly between the existing air inlet and exhaust fan(s) and eliminate any type of obstruction that could deter airflow along that path. One way to help guide fresh air to the calf level is to build a box extending from the exhaust fan within three or four feet of the calf pen floor. If possible, place the youngest calves directly next to the air inlet. This will provide the cleanest air to the most susceptible calves. In this scenario, the speed of incoming air can only be as fast as the youngest calves can handle, especially during cooler temperatures. This may be a limiting factor to the amount of fresh air volume delivered to the oldest calves in the barn.

Calves housed in individual pens require a more evenly distributed source of fresh air, one that will not be redirected by the frequent obstruction of solid side panels. The ideal method of delivery is through a positive pressure tube, which will ensure even, fresh air distribution throughout the entire length of the barn. Positive pressure tubes can be placed directly over the individual pens and blow unobstructed air straight into the calf’s space. These tubes can be paired with existing exhaust fans to create a neutral pressure ventilation system and can be used in group pen situations as well.

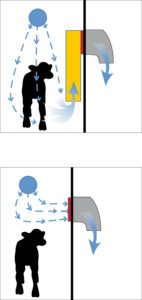

A multi-season positive pressure tube will allow you to appropriately ventilate in both warm and cool weather conditions using a single system. Multi-season tubes use an internal membrane that separates two very different hole patterns on opposite sides of the same tube. Large holes line the bottom of the tube and allow large amounts of rapid, fresh air to reach calves during warm weather. During cool weather, a lever mechanism connected to the fan can be used to adjust the internal membrane to the bottom of the tube, blocking the large diameter holes and redirecting the air out of the small holes in the top of the tube, away from the calves. Forcing air through small holes in the top of the multi-season tube is ideal for a stanchion barn because it enables air discharged out the top of the tube to bounce off the barn’s low ceiling, causing it to gently fall into the calf pen(s) below. This low volume, slow air is ideal for calves during cool weather. (See Figure 1)

Figure 1.: A multi-season positive pressure tube will allow you to appropriately ventilate in both warm and cool weather conditions.

Single season positive pressure tubes can also be used seasonally when appropriate. In this situation, a number of cold weather tubes typically run all year and can either be paired to run with warm weather positive pressure tubes or a combination of natural ventilation with mechanical fan assistance. Warm weather tubes can be run when temperatures are consistently above 70 degrees Fahrenheit to provide rapid air speeds for heat abatement.

The space requirement that a positive pressure tube requires in the barn must be considered before installation. Stanchion barns traditionally have very low ceilings that may already make pen cleanout a difficult process. A positive pressure tube typically occupies at least one to two feet of headspace once installed. In situations where space is tight, the tube fan can be turned off and the positive pressure tube pushed back to the fan, increasing the height limit to the cables securing the duct. Once cleanout is complete, simply stretch out the tube and turn on the fan to allow the duct to resume its normal position.

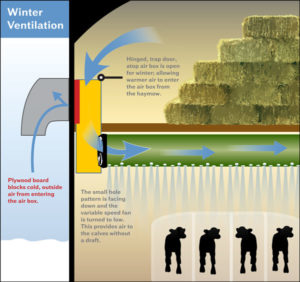

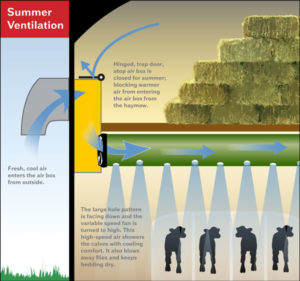

Because stanchion barns have solid walls, positive pressure tube fans will often be boxed in through a hay mow or attic, offering the unique advantage of pulling fresh, tempered air into the barn. Producers can construct an air box system that allows them to change the source of fresh air according to the season by connecting the box to an exterior wall. In the winter, the exterior wall is closed off, allowing warmer attic air to be drawn into the air box and distributed to the calves below. In the summer, the exterior wall is open and the attic space is blocked off, allowing cooler outside air to be drawn in. (See Figure 2)

Figure 2.: Producers can construct an air box system that allows them to change the source of fresh air according to the season by connecting the box to an exterior wall.

It is important to understand how the distance between the fans and the calves will affect the air speeds the calves experience, regardless of which type of ventilation is used in the barn. Due to the lower stanchion barn ceilings, fans will be much closer to calf height than if they were hung on a rafter in a newly built calf barn. The air projected from the fan has a shorter distance to travel to reach the calf, which means that it has less time to slow down, creating a greater risk for a drafty environment during cold temperatures.

While it is critical to provide the appropriate volume of fresh air to the calf year-round, it is equally important that the fresh air is delivered at the correct speed. This can be a challenge in many barns, so make sure to assess the ventilation system efficiency in every season before determining its suitability for the barn.

Retrofitting a stanchion barn for calves can be an extremely efficient way to reallocate existing space and resources on a farm. Carefully examining calf ventilation requirements prior to moving the calves into the barn will help prevent respiratory issues. The time and effort spent researching ventilation designs and options will be well worth the investment when that ‘old dairy barn’ transitions from representing the farm’s history to raising the farm’s future.

This article was originally published with the Progressive Dairyman Magazine at: