Click here to view as a pdf: Next Step In Calf Barn Ventilation: Computer-Based Airflow Simulations and 3D Modeling

By: Nele Leiterman, D.V.M.

We are excited to share with you the new technologies and approaches Crystal Creek’s ventilation team is now utilizing in our ventilation projects. In this article, the software tools, which have improved the way we design ventilation systems, will be explained. These digital tools allow us to obtain precise calculations, visualize airflow patterns, and create realistic 3D representations of barns and ventilation systems before they are even built.

Designing the System

Crystal Creek’s ventilation design considers a multitude of factors. The baseline factors are the number, age, and size of calves, combined with the size of the barn and the style of housing. With this information we start the design. Calculations and target values, combined with our extensive experience, help us create a solid foundation for our projects. Real life limitations, such as height restrictions and neighboring buildings, are then also taken into consideration to ensure our ventilation systems fit seamlessly into each individual barn.

After the initial design process, we then create a digital representation of the barn using SolidWorks®, a widely used 3D modeling software. This allows us and our customers to visualize the finished system, explore various design possibilities, identify potential challenges, and optimize the system’s layout for maximum efficiency and effectiveness.

Computer-Generated Fluid Dynamics Improve FLAP DUCT® Designs

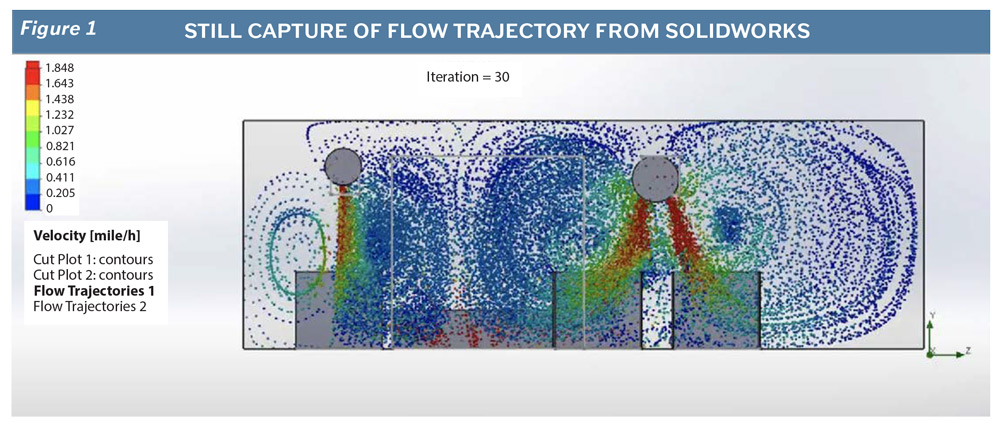

To further enhance the accuracy of our designs, we rely on SolidWorks® Flow Simulation software. This computational fluid dynamics (CFD) tool enables us to digitally simulate and calculate the airflow throughout the barns, and most importantly, at the calf level. By comparing this simulation with the existing conditions, we can make data-driven decisions to fine-tune our design and ensure optimal airflow throughout the structure. Our ventilation systems are focused on high-volume, fresh air delivered to the calves. With the Flow Simulation software, we can predict the volumes of fresh air reaching each calf and the speed of air inside the calf’s microclimate in the different seasonal settings of Flap Duct®. These results allow us to predict the efficacy of the system.

Click here to watch the Next Step In Calf Barn Ventilation: Computer-Based Airflow Simulations and 3D Modeling video.

3D Visualization of Entire Barns

One of the most useful aspects of our design process is the visualization tools that bring our concepts to life. Just like a fogging test in the newly installed system, these tools provide a stunning visual representation of how the airflow will behave in the new structure.

Using Unreal® Engine, a professional design software, we create detailed 3D models of barns that haven’t been built yet and can then showcase how the FLAP DUCT® system will be integrated into both new and existing barns. Moreover, we take this visualization a step further by animating the airflow patterns for various scenarios, allowing our clients to witness the effectiveness of our ventilation solutions before implementation.

By leveraging the power of SolidWorks®, Flow Simulation, and Unreal® Engine, our ventilation work has reached new heights of precision and efficiency. These technologies enable us to design, calculate, and visualize the airflow in a structure before construction even begins, allowing us to fine-tune our solutions for the best possible outcomes. Our goal continues to be delivering the most effective and sustainable ventilation solutions for our customers’ needs.