Nutritional And Management Considerations In Robotic Milking Facilities

Click here to view as a pdf: Nutritional and Management Considerations In Robotic Milking Facilities

By Erik Brettingen, B.S.

By Erik Brettingen, B.S.

Robotic milking systems are becoming increasingly common in the dairy industry. Milking with robots provides benefits for both the dairy farmer and the cow. For the dairy farmer, robots take stress off a difficult labor situation and allow more flexibility of time. They allow time that would have been spent milking to be spent on potentially higher value activities like herd management tasks, making quality forage, and more time with family. For the cows, robots can improve comfort by allowing more expression of natural cow behavior. Especially in free flow systems, cows can move about the barn as they please, get milked when they want, and rarely experience time standing when they would rather be laying or eating. Like anything, along with the benefits also come a few difficulties. Feeding cows in a robotic milking system can have some challenges but a few key concepts have been proven to help create success. Exceptional forage quality, robot concentrate palatability, transition cow performance, and a rumen focused formulation strategy all contribute to sustainable and profitable production in robot herds.

Exceptional Forage Quality

The two-part ration in robot herds does create a slightly different method of feeding. The partial mixed ration (PMR) is the feed the cows receive in the bunk made up of the forages and a portion of the concentrate. The remaining concentrate is delivered to the cow in the robot as they are being milked. The amount of feed a cow receives in the robot is determined by a feeding table set up by stage of lactation and production. The balance between the PMR and the robot concentrate is important. If cows consume too much energy in the PMR, they may neglect to visit the robot to consume concentrate and get milked. If the PMR is lacking in energy, milk production and cow health may suffer.

With cows consuming the robot concentrate on their own, there is an unavoidable slug feeding situation that does not occur in TMR fed herds. This increases the need for high quality forage. Poor forage quality can lead to high starch, low forage PMR’s. This is a disaster when paired with the slug feeding happening at the robot, especially if a high level of concentrate is offered. This situation leads to low rumen pH and rumen acidosis. When forage quality is very good, the PMR can provide adequate energy with high levels of forage. Forages that are highly digestible allow for increased intake and provide the cow with more energy and more digestible fiber to generate microbial protein. Focusing on neutral detergent fiber digestibility is key.

Robot Concentrate Palatability

The concentrate that is fed through the robot can be thought of as an incentive or the “treat” that helps bring the cows to the robot to get milked. Most robotic dairies rely on a pellet to feed through the robot. Pellets are denser and easier to consume quickly by the cow. Pellets also reduce the fines potentially left in the feed bowls at the robot. Some dairies feed ground concentrate through the robot with great success. This typically provides significant cost savings and can increase the likelihood of customizing your concentrate feed. Regardless of the physical form, the nutrient makeup of the robot concentrate determines the palatability. Palatability of the robot grain can become an issue when the pellet is being relied on too heavily as part of the ration. When nutritionists try to significantly increase nutrient density in the pellet, ingredients like blood meal, mineral feeds, amino acids, and some fats can create an off taste to the cows. This is counterproductive and reduces milkings and in turn, reduces milk production.

Transition Success Is Key

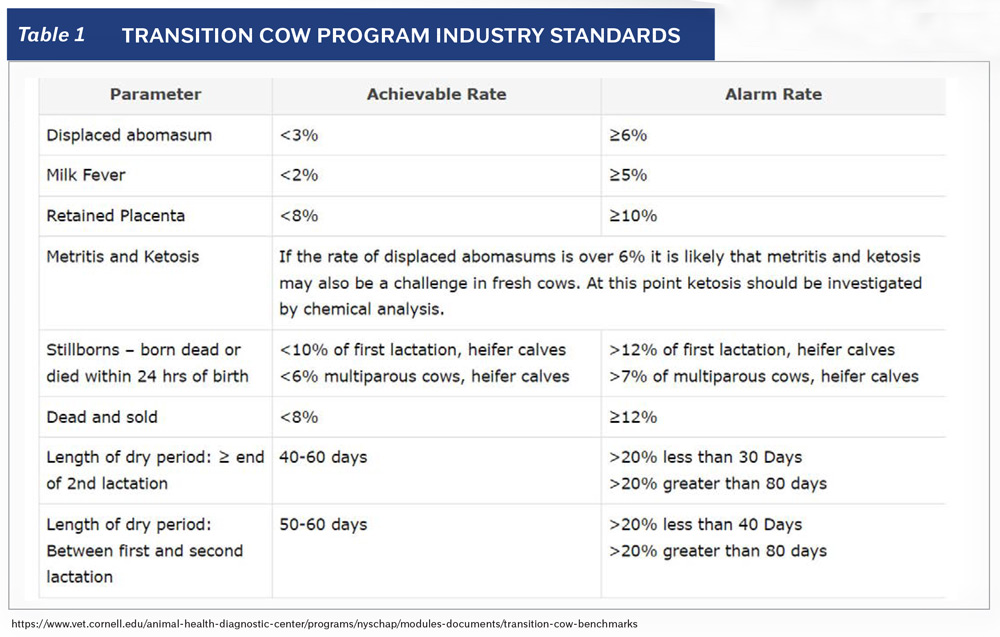

One of the biggest benefits of robotic milking systems is the ability of the cow to make frequent visits to the robot in early lactation. Ideally, cows ramping up to peak milk production will visit the robot four, five or even six times a day. This increase in milking frequency significantly increases milk production compared to milking two times a day. For a cow to want to go to the robot, get milked, and eat in the robot, she needs to feel healthy. Cows that freshen with metabolic challenges like milk fever, ketosis, retained placenta, or acidosis struggle more in a robot herd. They are not being walked to the parlor 2 or 3 times a day. They become fetch cows, fall behind on milking, don’t get their robot grain and never peak like they should. A successful pre-fresh ration is key to a good transition. Energy, protein, and DCAD levels are the largest contributing factors to a quality pre-fresh ration. Along with the correct nutritional makeup, the physical diet structure must be adequate as well. This includes feed particle length, feed cleanliness, and whether the cows can sort the ration. The table above, from Cornell, outlines some industry standard benchmarks to determine how well a transition cow program is working.

Rumen Focused Formulation Strategy

Most importantly, working with a nutritionist that understands robotic milking systems and your goals is crucial. It is important to remember the robots are a milking system, not a feeding system. It is not uncommon to visit prospective herds that may be feeding as much as 20 or 22 lbs. of concentrate through the robot to their high producing cows. This is a sign of nutritional frustration and entirely too much reliance on robot concentrate to provide nutrition. A cow is a cow regardless of the system she is in. This means the biologically appropriate rules of feeding a cow still apply in a robotic setting. It is very difficult to maintain rumen health when the robot feed is being relied on as a major part of the ration. When cows are eating that much feed in the robot, rumen pH drops significantly after each meal. This reduces rumination and decreases appetite. Reduction in dry matter intake causes a drop in milk production and less visits to the robot. The robot concentrate is also one of the most expensive portions of the ration. Focusing on higher forage rations and balancing the total ration around a better PMR reduces the need for as much robot pellet and generally produces more milk. A University of Wisconsin study found herds feeding higher levels of concentrate in the robot produced less milk. While the nutrient densities of high concentrate diets may look great on paper, too much concentrate increases passage rate of feed through the cow, reduces digestion, and leads to more cow health issues. Studies have also shown that simply increasing the feed in the robot does not increase dry matter intake. Cows will reduce PMR intake when robot concentrate feeding rate is increased. A study conducted in 2018 found for every 2.2 lb. increase in robot feed, there was a corresponding decrease in PMR intake of 3.5 lbs. Feeding too much concentrate in the robot is counterproductive and fails to adhere to the sound principles of feeding cows.

Robotic dairies do require a slightly different approach. But cows that are milked in robotic systems are still cows. Principles of good, solid ruminant nutrition still apply and rumen function and cow health always come first. If you would like to learn more about how Crystal Creek® works with robotic dairies or are interested in ration balancing services, please call 1-888-376-6777 or visit www.crystaclcreeknatural.com to speak with a Crystal Creek® dairy nutritionist.

References available upon request.