Recognizing The Need For Disinfection In Your Poultry Operation

Click here to view as a pdf: Recognizing The Need For Disinfection In Your Poultry Operation

By Stephanie Hutsko, PhD

Why do we need to have a disinfection plan in place when working with livestock, especially poultry? One word: pathogens.

Pathogens are bacteria or viruses that, when exposure levels are high enough, can cause disease. When bacteria are left uncontrolled, their numbers grow quickly, wreaking havoc on the birds exposed to them. A common parasite associated with poultry, Eimeria sp, can lead to coccidiosis. Common bacteria associated with poultry include Salmonella and E. coli, both of which can lead to food safety concerns. The main poultry viruses we are concerned about are Newcastle disease, Marek’s disease and Avian Influenza.

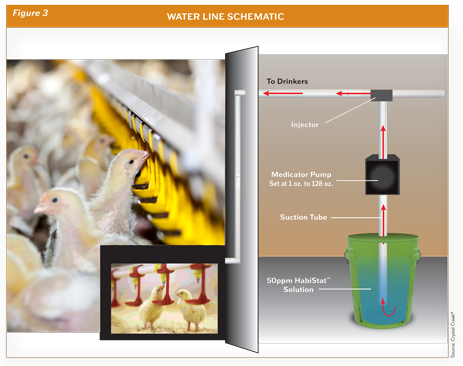

Bacteria, single celled parasites and viruses can also evolve into protected communities, called biofilms. Biofilms have a defensive barrier that shield the pathogens within it from potentially harmful materials and compounds. As mentioned in a previous article in the April 2017 Crystal Creek® Newsletter, in Jessica Getschel’s article, “Understanding Biofilms in Agriculture”, biofilms have five stages of development (Figure 1). Traditional disinfectants, like peroxide or bleach, are ineffective in breaking down the biofilm’s protective layer. This means, that even if a surface looks visibly clean, it may not be biologically clean.

A full-blown disease outbreak can be devastating to a flock, especially when mortality rates start to rise, but what many producers don’t consider is the negative effects even low-level diseases can have on production and the overall efficiency of their operation. Important production factors to consider are feed conversion ratios, percent lay, body weight growth, egg quality, case weight and carcass weight. All of these factors can be negatively affected by pathogen exposure, and in the worst-case scenario increases in mortality can occur.

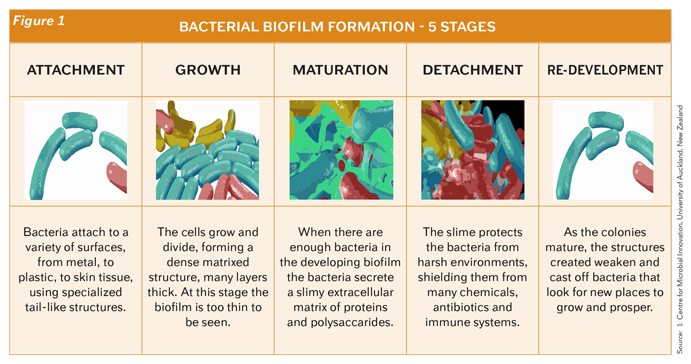

So, what is the solution? Crystal Creek® recommends implementing a cleaning and disinfecting protocol using a safe, effective and non-corrosive agent, such as chlorine dioxide. While many cleaning products use a form of chlorine (like bleach), chlorine dioxide is different in that it is produced as a soluble gas. When activated, this gas is trapped by water molecules, making it into a chlorine dioxide solution. Chlorine dioxide works through oxidation, which disrupts cellular membranes, eventually leading to death of bacteria and single celled parasites in a short amount of time (Figure 2).

Crystal Creek® Offers Cleaning And Disinfecting Solutions

Crystal Creek® has multiple options to address your disinfecting needs. For general cleaning purposes, the detergent Chlor-A-Foam™ is the best option. This alkaline detergent can be easily put into a foaming gun and sprayed onto any surface, such as cement floors, walls, even nesting boxes and roosts. The next step is to provide 10 to 15 minutes of contact time to allow for breakdown of any organic matter, scrub if necessary and then rinse with cold water.

HabiStat™, a chlorine dioxide disinfectant, comes in two easy to use forms: a ready to use tablet and a liquid activator/base set. The tablets simply need to be added to room temperature water in a sealable container and it is ready to use. The liquid activator/base also needs to be added to room temperature water, with the activator being added first and the base second. This solution needs to be left sealed for 12 to 24 hours before it is ready to use. Both options need to be made in a well-ventilated area.

Disinfecting On Farm

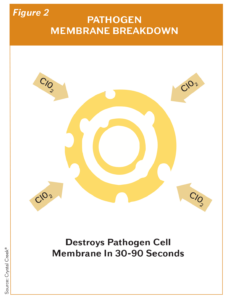

Not only does HabiStat™ come in two forms, it can also be used in two unique ways. The first is to disinfect poultry house water lines by running a low concentration solution of HabiStat™ through the line. This will clean and disinfect the lines themselves, getting rid of any biofilm and pathogen build up, and it can be done while the birds are still in the barn.

General protocol for use in waterlines:

- Make a 50ppm HabiStat™ solution by dissolving a 20g tablet in 10 gallons of room temperature water.

- Set the in-line dosage meter to a rate of 1 oz. to 128 oz. (or 1 oz. per gallon).

- Connect a hose from the 10 gallon bucket to the in-line dosage meter and run according to the manufacturer’s instructions at the above rate.

Ten gallons of a 50ppm solution will last approximately five days for a barn containing 5,000 birds and costs $10.50 per 20g tablet. A water line disinfecting system (Figure 3) can be of great benefit to your operation.

The second application is cleaning and disinfecting the poultry houses and facilities. This involves both the Chlor-A-Foam™ detergent followed by the HabiStat™ disinfectant spray. The detergent cleans the surface and begins the process of breaking open the biofilm protective barrier. The spray volatilizes into a gas that then seeps into any cracks or pores, thoroughly decontaminating the entire area.

General protocol for use in facilities:

- Remove all animals in the facility you intend to clean.

- Remove any debris and gross soil from surfaces.

- Spray Chlor-A-Foam™ onto the area, let it soak for 15 minutes, scrub and rinse with cold water.

- Spray with 100ppm HabiStat™ solution. Let air dry for 12 to 24 hours before repopulating.

If you are searching for a safe, effective and economic solution to your disinfecting issues, give Crystal Creek® a call and our knowledgeable staff will help find an option that is right for your farm.