Ventilating A Retrofitted Stanchion Barn For Calves

Click here to view as a pdf: Ventilating A Retrofitted Stanchion Barn For Calves

By Jessica Getschel, B.S.

There’s nothing more picturesque than a dairy farm with a big red barn on a cobblestone foundation. Many of these barns, referred to as stanchion, tiestall or bank barns, were built decades ago and tell stories of families who have been dairy farming for generations.

Over the years, many farmers have moved out of these older barns and into modern freestall barns for a variety of reasons: expanding herd size, new cow comfort recommendations or a new milking system, to name a few. This departure leaves a vacant building prized for its emotional value to the farm.

Rather than demolishing the barn or leaving it to harbor cobwebs, many dairy producers are choosing to put this space to good use: housing their calves.

An old stanchion barn is an excellent space for calf housing. It is an existing structure more affordable to retrofit than building a new facility. It provides a covered space that already has electricity and water available. The milk room attached to the barn that previously housed a bulk tank and milking equipment can easily be converted to a milk preparation room. This space can also be effectively utilized for cleaning and sanitizing feeding equipment.

For the sake of calf health, ventilation and the factors that impact it should be carefully considered before placing young calves in an old dairy barn. These barns tend to have very little opportunity for natural ventilation and rely considerably on mechanical ventilation.

If the mechanical ventilation is not appropriately modified for calf housing, air quality will plummet as moisture and gases build up. Poor air quality will be detrimental to calf health and can significantly outweigh any benefits that may be gained from indoor housing.

Many stanchion barns come equipped with existing tunnel ventilation or a similar negative-pressure system. Utilizing the barn’s existing ventilation can help you avoid additional remodeling costs, but it may also lead you to assume the calves’ ventilation requirements are met. Chances are, they are not. Producers should evaluate air speeds and perform a fogging test to determine whether the current ventilation is appropriate for the calves and their location in the barn before populating it with calves.

Before committing to a ventilation plan, consider if the calves will be housed in group pens or individually. Group-housed calf pens are much easier to ventilate due to the openness of the space. For group housing, position the calf pens directly between the existing air inlet and exhaust fans and eliminate any type of obstruction that could deter air flow along that path.

One way to help guide fresh air to the calf level is to build a box extending from the exhaust fan within 3 or 4 feet of the calf pen floor. If possible, place the youngest calves directly next to the air inlet. This will provide the cleanest air to the most susceptible calves.

In this scenario, the speed of incoming air can only be as fast as the youngest calves can handle, especially during cooler temperatures. This may be a limiting factor to the amount of fresh air volume delivered to the oldest calves in the barn.

Calves housed in individual pens require a more evenly distributed source of fresh air, one that will not be redirected by the frequent obstruction of solid side panels. The ideal method of delivery is through a positive-pressure tube, which will ensure even, fresh air distribution throughout the entire length of the barn.

Positive-pressure tubes can be placed directly over the individual pens and blow unobstructed air straight into the calf’s space. These tubes can be paired with existing exhaust fans to create a neutral-pressure ventilation system and can be used in group pen situations as well.

A multi-season positive-pressure tube will allow you to appropriately ventilate in both warm- and cool-weather conditions using a single system. Multi-season tubes use an internal membrane that separates two very different hole patterns on opposite sides of the same tube. Large holes line the bottom of the tube and allow large amounts of rapid, fresh air to reach calves during warm weather.

During cool weather, a lever mechanism connected to the fan can be used to adjust the internal membrane to the bottom of the tube, blocking the large-diameter holes and redirecting the air out of the small holes in the top of the tube, away from calves.

Forcing air through small holes in the top of the multi-season tube is ideal for a stanchion barn because it enables air discharged out the top of the tube to bounce off the barn’s low ceiling, causing it to gently fall into the calf pens below. This low-volume, slow air is ideal for calves during cool weather (Figure 1).

Single-season positive-pressure tubes can also be used seasonally when appropriate. In this situation, a number of cold-weather tubes typically run all year and can either be paired to run with warm-weather positive-pressure tubes or a combination of natural ventilation with mechanical fan assistance.

Warm-weather tubes can be run when temperatures are consistently above 70˚F to provide rapid air speeds for heat abatement.

The space requirement a positive-pressure tube requires in the barn must be considered before installation. Stanchion barns traditionally have very low ceilings that may already make pen cleanout a difficult process. A positive-pressure tube typically occupies at least 1 to 2 feet of headspace once installed.

In situations where space is tight, the tube fan can be turned off and the positive-pressure tube pushed back to the fan, increasing the height limit to the cables securing the duct. Once cleanout is complete, simply stretch out the tube and turn on the fan to allow the duct to resume its normal position.

Because stanchion barns have solid walls, positive-pressure tube fans will often be boxed in through a hay mow or attic, offering the unique advantage of pulling fresh, tempered air into the barn.

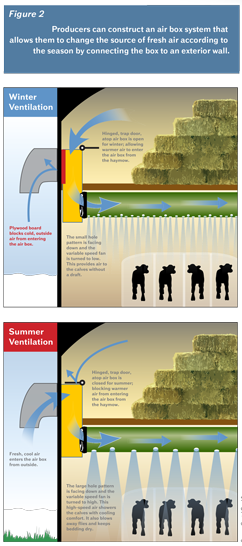

Producers can construct an air box system that allows them to change the source of fresh air according to the season by connecting the box to an exterior wall. In the winter, the exterior wall is closed off, allowing warmer attic air to be drawn into the air box and distributed to the calves below. In the summer, the exterior wall is open and the attic space is blocked off, allowing cooler outside air to be drawn in (Figure 2).

It is important to understand how the distance between the fans and the calves will affect the air speeds the calves experience, regardless of which type of ventilation is used in the barn. Due to the lower stanchion barn ceilings, fans will be much closer to calf height than if they were hung on a rafter in a newly built calf barn.

The air projected from the fan has a shorter distance to travel to reach the calf, which means it has less time to slow down, creating a greater risk for a drafty environment during cold temperatures.

While it is critical to provide the appropriate volume of fresh air to the calf year-round, it is equally important the fresh air is delivered at the correct speed. This can be a challenge in many barns, so make sure to assess the ventilation system efficiency in every season before determining its suitability for the barn.

Retrofitting a stanchion barn for calves can be an extremely efficient way to reallocate existing space and resources on a farm. Carefully examining calf ventilation requirements prior to moving the calves into the barn will help prevent respiratory issues.

The time and effort spent researching ventilation designs and options will be well worth the investment when that “old dairy barn” transitions from representing the farm’s history to raising the farm’s future.

This article was originally published with the Progressive Dairyman Magazine at:

https://www.progressivedairy.com/topics/calves-heifers/ventilating-a-retrofitted-stanchion-barn-for-calves