Dairy Goats Benefit From High Quality Nutrition

Click here to view as a pdf: Dairy Goats Benefit From High Quality Nutrition

By Dan Leiterman

Goats are competent browsers, which leads to the misconception that goats can eat and thrive on almost anything. In reality, because goats have a shorter digestive system relative to their body size, food is not retained as long. This increases the need for both higher levels of nutrition and higher quality nutrients. This faster digestive pass through time, reduces nutrient absorption, but also allows goats the ability to increase their dry matter intake to offset the short access time to nutrition. The range of dry matter intake for goats is 3 to 5 % of their body weight which is typically higher than other ruminants.1

A goat’s diet may consist of a wide variety of feedstuffs. Goats can browse on shrubs, graze on pasture and can accommodate supplemental grain feeding when necessary to meet nutritional requirements during times of higher production or winter months.

Advanced Nutrition In Crystal Creek® 37% Goat Pellets

Crystal Creek® 37% Goat Pellets contain high performance features that make an excellent foundation for meeting the higher nutritional needs of both milking and meat goats. For example:

1) High quality ingredients such as cleaned phosphorus reduces nutrition blocking contaminants in the diet and supports energy utilization.

2) 100% trace mineral fortification with polysaccharide chelates for improved support of immune function, lower somatic cell count, reproductive performance and mammary health.

3) Strong fortification levels of trace mineral (especially copper) and vitamins to support optimum health and production.

4) Crystal Creek® 37% Goat Pellets do not contain cheap fillers such as distillers grains.

Using Crystal Creek® 37% Goat Pellets to formulate a complete grain mix will not only meet the higher needs of producing goats, but will simplify formulation and enhance the palatability of the diet.

Example 16% Grain Mix Made With Crystal Creek® 37% Goat Pellet

The nutrient requirements for milking goats have a wide range. Variables such as, the number of kids, level of milk production, environmental conditions, and the size, breed and age of the doe are all examples that affect nutrient requirements. The following (Figure 1) is an example of a typical 16% grain mix made with the Crystal Creek® 37% Goat Pellet.

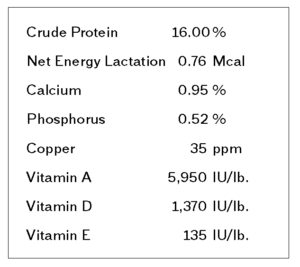

Figure 1. 16% Complete Grain Mix For Milking Goats And Growing Goats

Corn 860 lb.

Oats 500 lb.

CC, 37% Goat Pellets 540 lb.

Liquid Molasses 100 lb.

Total 2,000 lb.

Feeding Grain To Milk Goats

It is recommended you have a Crystal Creek® Nutritionist balance the diet for your goats. General guidelines for feeding grain to goats can be helpful. Because of the wide variation in feedstuffs it is best to feed a ration that has been balanced by a competent nutritionist.

- Start a doe on grain one month before kidding, and target 1.5 pounds of grain/hd./day by kidding time.1

- After kidding, increase grain slowly to about 3 pounds/hd./day. This is usually accomplished by 4th week post-kidding.1

- After peak lactation, feed according to milk production. Feed approximately 0.33 lb. of grain per lb. of milk production. Split the daily grain feeding into two feedings.

- Try not to feed a doe more than 4 pounds of grain per day.2

Crystal Creek® offers a wide range of nutritional and animal comfort products that are beneficial to supporting your goals in goat production. Check out our website at www.crystalcreeknatural.com and learn more about the innovative Crystal Creek® family of products and services. Our friendly technical staff is available to answer any questions you may have. Call today and plan a winning strategy for your operation.

Source:

- Feeding Dairy Goats, University of Minnesota Dairy Extension, Laura Kieser.

- Smith, 1994.