Crystal Creek® is proud to present Dr. Ryan Leiterman’s recent articles published in the Progressive Dairyman Magazine.

Progressive Dairyman will be featuring three of Dr. Leiterman’s articles on calf barn ventilation this year. Dr. Leiterman is the Director of Technical Services at Crystal Creek® and holds degrees in both veterinary medicine and agricultural engineering.

ARTICLE #1

Crank Up Your Fans To Improve Summer Calf Performance

Click here to view as a pdf: Crank Up Your Fans To Improve Summer Calf Performance

Summer heat can be just as, if not more, stressful for calves than winter. Keeping them cool and healthy boils down to achieving adequate air exchanges per hour and a 2 to 5 mph breeze. Heat stress is a major concern for calves. Research has proven calves suffer from heat stress in much the same way cows do. A calf ‘s temperature threshold can be easily reached during summer months. A daily temperature exceeding 77 ºF can prevent calves from dissipating accumulated heat and result in performance declines.

Calves born during summer months have been shown to have lower average daily gains, reduced feed intake, increased maintenance energy needs and reduced immune function. These factors can result in poor growth and higher susceptibility to disease. Providing proper nutrition, ample shade and access to fresh water are all important factors in combating heat stress. However, one common tactic deserving more attention is calf housing ventilation.

Crank up the fans!

Increasing ventilation rates is one of the most effective ways to reduce heat stress among calves. Air speeds from 2 to 5 mph have been shown to have a cooling effect and are beneficial to calf health and performance during times of heat stress. High-speed cooling air offers the additional benefits of reduced fly pressure and drier bedding.

Picture 1: The open pen layout of group housing generally lacks significant air flow obstructions, allowing summer breezes and high-speed air from panel fans to easily reach and cool calves.

It is crucial to match the appropriate ventilation system to your calf housing style. Calf raisers using bedded packs and group housing can successfully ventilate their calf spaces with a combination of positive-pressure tubes, panel fans and curtain sidewalls. This is because the large open spaces of bedded packs generally lack air flow obstructions, allowing the cooling air from panel fans and natural summer breezes to easily reach calves. In the summer, open curtain sidewalls and panel fans turned on high provide large volumes of high-speed air to help keep calves cool.

Panel fans and natural ventilation do not work well in providing cooling summer air flow to calves in individual pens. This is because the solid panels between calves often act as significant air flow obstructions and limit the amount of air reaching the calf. All too often, as summer air flow from panel fans or natural ventilation moves toward the pens, it deflects off the solid panels and is prevented from reaching calves.

Picture 2: The solid sidewalls that separate calves in individual pens no longer act as significant air flow obstructions when a positive-pressure tube is centered above each row. High-speed air is discharged straight down into the pens at 5 mph to provide cooling comfort to calves during summer months.

The best way to prevent heat stress in calves housed in individual pens is to center positive pressure tubes, designed specifically for summer heat abatement, directly over the pens. This allows large volumes of fast air to be discharged straight down into the pen without being blocked by the solid panels between calves.

The dairy in Picture 2 uses individual pens coupled with a multi-season positive-pressure tube centered over each row. Multi-season tubes can be adjusted to increase or decrease the air flow delivered to calves based on the season. This multi-season tube is set for fast summer air flow and all of the air is being discharged out large holes in the bottom of the tube, directly into the calf pens. Fog has been introduced to help visualize the air flow. Each calf pen is 4 feet wide, 4 feet tall and 7 feet long, or 112 cubic feet. This particular multi-season tube is designed to discharge 148 cubic feet of air per minute to each calf at a speed of 5 mph during the summer. As a result, each calf receives a new pen full of fresh air (112 cubic feet) every 45 seconds, resulting in 79 pen volume changes every hour. This high volume and speed of air greatly benefits calves during hot weather by providing cooling air flow while keeping bedding dry and reducing fly stress. Summer ventilation tubes can also achieve these results.

See it for yourself

Trained ventilation experts can help evaluate the effectiveness of your calf barn ventilation system. These experts use air speed and volumetric flow meters, fogging devices and design software that aids in evaluating system performance.

That said, you do not have to be a ventilation expert to get an idea of how your ventilation system is performing. For instance, you can watch the air flow in your calf barn by fogging. Fogging devices enable you to visualize where the air is moving – or is not moving, in the case of dead spots. Fogging also provides an approximation as to the number of air exchanges per hour.

To evaluate your ventilation system:

- Use a fogging device as shown in Picture 3. The fog will be sucked into the fan and discharged towards calves; allowing you to see air flow in the barn. The fog generated will not harm the calves.

Once an area is filled with fog, time how long it takes to clear out. Use that time to calculate the number of air exchanges your system is providing. Take the number 60 and divide it by the time, in minutes, it took for the area to clear. For example, if it takes six minutes for the fog to clear (60 / 6 = 10), the system is providing approximately 10 air exchanges per hour. Current industry guidelines suggest barns receive 40 air exchanges per hour in the summer. However, this recommendation looks at ventilation on an entire barn level rather than at the calf level. When watching how the fog clears the barn, pay close attention to how the pens clear the fog to understand what is happening at the calf level.

- Measure air speeds at the calf level. Air speeds of 2 to 5 miles per hour provide a cooling effect. Inexpensive air speed meters, or anemometers, can be purchased online and generally cost between $25 and $100. These meters use miniature fan blades that spin when placed in an air stream. Ventilation professionals generally use more expensive air speed meters called hot-wire anemometers. These air speed meters are more accurate but can cost over $1,500.

If you want to skip the technical measurements and just eyeball it, a good summer ventilation system will blow air on the calves fast enough to cause straw or stover bedding to gently wave in the breeze. Heat stress is important to address to ensure successful calf rearing. Before simply cranking up the fans, check to see your ventilation system is delivering the correct volume and speed of fresh air for heat abatement. Look yourself or seek the assistance of a ventilation professional to determine whether your calves are getting the proper ventilation needed to improve their performance during summer heat stress.

This article was originally published with the Progressive Dairyman Magazine at:

ARTICLE#2

Keep Calves Off The Termperature Roller Coaster

Click here to view as a pdf: Keep Calves Off The Temperature Roller Coaster

Spring and fall weather conditions often present calf raisers with the challenge of fluctuating temperatures. The rapid and ongoing transition from warm days to cold nights creates a temperature roller coaster that can increase calfhood respiratory disease rates.

The ventilation rates applied to calf barns are based on outside weather conditions, namely the ambient air temperature. During warmer weather, calf barns are ventilated with an increased volume and speed of fresh air. Conversely, during cold weather, calf barns are ventilated with lower volumes and slower fresh air speeds to prevent a draft.

Ventilation systems that cannot be adjusted in response to changing outside temperatures will leave calves over or under ventilated. To best cope with the ever-changing spring and fall weather conditions, calf barn managers must be able to quickly and easily adjust their ventilation systems to increase or decrease the volume and speed of fresh air throughout the day.

Calf raisers use different ventilation systems with varying degrees of success. However, a good ventilation system must:

- Provide the correct volume of fresh air based on seasonal requirements by increasing volume during warm weather and decreasing volume during cold weather.

- Evenly distribute fresh air to the calf.

- Deliver fresh air to the calf at the correct speed based on the season; faster speeds (200-400 feet per minute) for warm weather heat abatement; slow, non-drafty speeds (less than 50 feet per minute) during cold weather.

- Provide for easy adjustment of fresh air volume and speed in response to the warm days and cold nights of spring and fall.

Below are three types of calf barn ventilation systems that are able to meet these criteria.

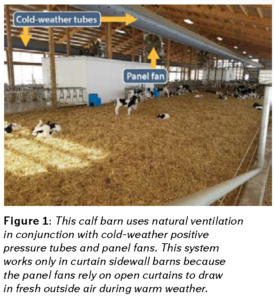

- Cold weather positive-pressure tubes with panel fans

This tube system contains numerous small holes (typically .75-to 1.5-inch diameter) that release a slow, gentle blanket of fresh air for cold weather ventilation (Figure 1). Although the tubes are designed for cold weather use and only minimally contribute to warm weather ventilation, it is important to run this system in the summer when the curtain sidewalls are open because an inflated tube remains taut and less prone to wind damage.

During spring and fall, curtain sidewalls are progressively opened from the bottom as the weather warms. Variable speed basket or panel fans can be turned on low to slowly increase air speed as needed. For heat abatement during warm weather, curtains are opened completely, and the basket or panel fans operate on high to circulate the incoming fresh air at high speeds.

Variable-speed basket or panel fans can quickly and easily be manipulated in conjunction with the curtain sidewalls to adjust both the volume and speed of fresh air delivered to the calf. Thermostatic controllers and total weather stations can completely automate the process.

This type of system is best suited to the open pen layouts of automatic calf feeders or post-weaned pens. It is not advisable to use this type of system in calf barns with solid-sided individual pens. Basket or panel fans direct air downward at roughly a 30-degree angle. When air blows across a row of individual pens with solid sides, the sidewalls deflect air and prevent it from reaching the calf.

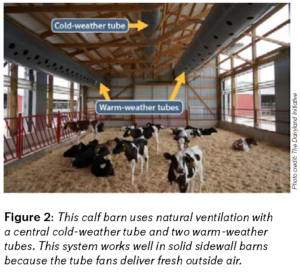

- Warm weather and cold weather positive-pressure tubes

This system combines multiple positive-pressure tubes, each designed for different seasonal applications (Figure 2). While commonly used in combination with curtain sidewalls, this system is not dependent on them because the tubes bring in fresh outside air. Consequently, it can be used in solid wall buildings as well.

These systems typically have multiple warm weather tubes with large-diameter holes for fast, high volume airflow and a single cold weather tube containing numerous small-diameter holes for slow, gentle air distribution. The tubes can direct fresh air straight down into a row of individual pens without the pen’s solid sides blocking air flow.

Warm weather tube fans are most commonly single speed and are turned on/off as needed. Closing curtains when the warm weather fans are off will prevent wind damage to the deflated tubes. These fans can be automated to turn on/off with a thermostatic controller, making them effective tools to handle the warm days and cold nights of spring and fall.

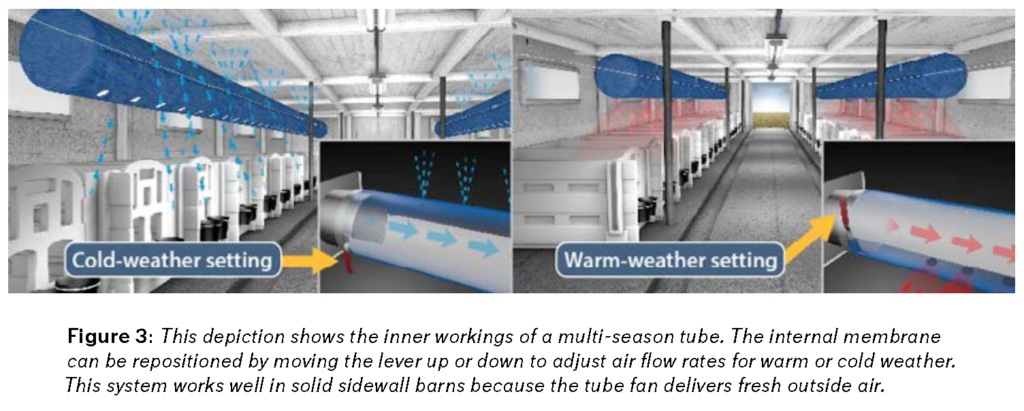

- Multi-season positive-pressure tubes

Multi-season tubes combine warm weather and cold weather positive-pressure tubes into one unit. Each tube contains an internal membrane that runs the length of it. This membrane is used to block, restrict or change direction of air exiting the tube, achieving the desired airflow based on seasonal requirements. These systems are connected to variable speed fans and have an array of numerous small holes on one side of the tube and fewer, larger holes on the opposite side. When the fan is turned on, air pressure pushes the internal membrane against an inside wall of the tube. The membrane blocks one of the hole patterns while exposing the other. This allows air to be discharged out the small hole pattern for cold weather or the large hole pattern for warm weather.

Like the cold and warm season tubes, multi-season tubes can also be used to rapidly and easily adjust fresh air volume and speed to match the warm days and cold nights of spring and fall.

The multi-season tube is placed over the calf pen area and during warm weather the larger hole pattern is pointed down towards the calves. The variable speed tube fan is turned on high, increasing the volume of air delivered. The large holes release robust jets of air, delivering fast, cooling air to the calf.

When the weather cools, a lever mechanism connected to the fan can be used to adjust the internal membrane to the bottom of the tube, blocking the large diameter holes and redirecting the air out of the small holes in the top of the tube, away from the calves. At the same time, the variable speed fan is turned on low, reducing the output. This style of multi-season tube is particularly useful for retrofitted stanchion barns because the air discharged out the top of the tube bounces off the low ceiling and gently falls into the calf pen.

In the winter, producers who have barns with taller sidewalls will commonly use a rotating mechanism to adjust the tube so the small holes are open, facing down towards the calves to discharge a gentle blanket of fresh air.

Multi-season tubes are being used successfully in every type of calf barn style and pen layout and eliminate the additional expense of warm weather fans.

What is right for your farm?

Having a proper ventilation system that keeps your calves comfortable and off the spring and fall temperature roller coaster is essential to raising healthy calves. Consult a ventilation professional to help you determine which system will work best for your operation’s ventilation needs.

This article was originally published with the Progressive Dairyman Magazine at:

http://www.progressivedairy.com/topics/calves-heifers/keep-calves-off-the-temperature-roller-coaster

ARTICLE #3

Winter Calf Barn Ventilation: Can Calves Have Too Much Fresh Air?

Click here to view as a pdf: Winter Calf Barn Ventilation- Can Calves Have Too Much Fresh Air

Cold temperatures are here and winter is quickly approaching. As the temperatures drop, calf barns are closed up and the ventilation rates are turned down. As an industry we do this reflexively, but is it what’s best for the calves?

Studies show that pre-weaned calves raised in hutches have lower pneumonia rates when compared with calves raised in barns. Even calves raised in calf barns equipped with modern ventilation systems can experience increased respiratory disease rates when compared with their hutch-raised counterparts.

Current calf barn ventilation guidelines suggest that as temperatures cool, the volume of fresh air brought into the barn should decrease. I would like to humbly challenge this assumption. After all, hutch-raised calves have been challenging this concept for years. Hutch calves do not have their volume of fresh air reduced during cold weather. Once outside the hutch, calves have an unlimited volume of fresh air to breathe, regardless of the season. For these reasons, the current recommendation of providing calf barns with four fresh air exchanges per hour, often defined as minimal winter ventilation, should be revisited.

The fact that hutch-raised calves do not have nose-to-nose contact certainly helps prevent the spread of contagious pneumonia. Yet, the individual pens used in many calf barns also prevent nose-to-nose contact and these calves often have higher pneumonia rates than hutch-raised animals.

It seems counterintuitive that hutch-raised calves would have less respiratory disease than their barn-raised counterparts. Hutch-raised calves often experience more heat stress in the summer and colder temperatures in the winter. During wet spring months, it can be challenging to keep hutch calves dry. In winter, if the wind is blowing into the hutch, calves can be exposed to a dangerous draft. Yet from a respiratory disease standpoint, hutch-raised calves are still healthier than barn-raised calves. Their lower pneumonia rates suggest that having unlimited amounts of fresh, outside air to breathe offsets the environmental hardships hutch-raised calves experience.

‘Too much’ fresh air?

As a veterinarian working with calf raisers for the past eight Wisconsin winters, I have never had a client say, “Doc, sometimes I worry about my hutch calves having too much fresh air to breathe in the winter.”

If hutch calves thrive with an unlimited volume of fresh air to breathe in winter, why are we as an industry limiting our calf barns to only four air exchanges per hour during cold weather?

There is a belief throughout our industry that if we increase the volume of fresh air brought into a barn, it will be drafty on the calves. This belief stems from decades of experience with negative-pressure ventilation systems.

Negative-pressure ventilation systems use exhaust fans to suck air through a barn. The classic example of a negative-pressure ventilation system is a tunnel-ventilated stanchion barn. Multiple large exhaust fans pull air through the barn and overtop of the animals. As more fans are turned on, the volume of air sucked through the barn increases, subsequently increasing the air speed. With any negative-pressure ventilation system, the air speed flowing through the barn is directly related to the volume of air pulled through by the exhaust fans (see Figure 1).

In negative-pressure ventilation systems, higher airflow volumes result in faster air speeds through the barn. Lower airflow volumes result in slower air speeds through the barn.

These principles of negative-pressure ventilation have created the longstanding association that increasing fresh air volume increases speed. It makes sense, with a negative-pressure ventilation system, to reduce the volume of fresh air brought into the barn during cold weather; it’s the only way to avoid a draft on the animals. The principles of negative-pressure ventilation, to reduce fresh air volume during cold weather and increase it during warm weather, eventually became the basis of our current calf barn ventilation guidelines (see Table 1).

The current ventilation guidelines have remained unchanged for decades, while over the same time period, ventilation technology has improved dramatically. Today, many calf barns are ventilated using positive-pressure tube systems, which do not follow the same engineering principles as negative-pressure ventilation systems. Thus, it does not make sense to follow guidelines developed for negative-pressure ventilation when designing positive-pressure tube systems.

Positive-pressure tubes are different

Positive-pressure tube ventilation systems blow fresh, outside air into ductwork, commonly referred to as a tube, to evenly distribute it throughout the barn. The tube has specially designed holes that discharge fresh air out of the tube and into specific areas of the barn.

With negative-pressure ventilation, air speed and volume are linked; increasing one increases the other. This is not the case with positive-pressure tube ventilation. Air speed at the calf level is not dependent on the volume of air blown into the tube but rather the:

- Distance from the tube to the calf

- The longer the air has to travel, the slower it will be when it reaches the calves.

- Diameter of the discharge holes in the tube

- Small diameter discharge holes produce weak, thready air streams that quickly lose momentum, much like air blown through a small diameter straw. These weak air streams result in slow, gentle air reaching the calves. Numerous, small diameter holes in a ventilation tube are ideal for cold weather use.

- Large diameter discharge holes in a tube produce robust air streams with more momentum, much like a leaf blower with a large diameter nozzle. These robust air streams deliver fast, cooling air over longer distances. Fewer, large diameter discharge holes in a ventilation tube are ideal for warm weather use.

What does the future hold?

Our industry has the opportunity to expand the conversation about how we ventilate calf barns. The fact that positive-pressure tube ventilation can be used to increase winter ventilation rates beyond four air exchanges per hour brings into question the age-old concept of reducing fresh air volume during cold weather. This technology has exposed the need for new calf barn ventilation guidelines to be developed and implemented; guidelines that promote higher volumes of fresh air exchange during cold weather.

My experience has shown that numerous calf raisers are finding cold weather ventilation success with positive-pressure tubes that deliver non-drafty fresh air at exchange rates greater than four times per hour. These calf raisers have learned through experience that limiting the volume of fresh air coming into the barn was not in the best interest of the calves. After all, hutch-raised calves have shown for decades that in the absence of a draft, there is no such thing as “too much” fresh air.

This article was originally published with the Progressive Dairyman Magazine at: