Managing Mycotoxins In Feedstuffs: Mycotoxin Binder Strategies

Click here to view as a pdf: Managing Mycotoxins In Feedstuffs

Mycotoxins are highly poisonous compounds produced by molds that can grow on livestock feeds both in the field and in storage. Mycotoxins can seriously reduce production in livestock and can negatively affect the health of both livestock and humans alike. Stressful growing and harvesting conditions, such as drought or very wet weather, are conducive to higher mold growth resulting in more mycotoxins in the feed. Mycotoxins are common in livestock feedstuffs and it has been estimated that over one third of the global grain supply has mycotoxin contamination. Poor storage conditions, post-storage mishandling of feedstuffs and poor bunk management may encourage further mold growth once the crop is out of the field.

There are over 300 different types of mycotoxins. At least 30 of these mycotoxins can be prevalent in livestock feedstuffs and several are highly toxic. Some of the more prevalent mycotoxins in livestock feeds are aflatoxin, deoxynivalenol (DON or vomitoxin), zearalenone, fumonisin, T2 toxin and ochratoxin.

Effects Of Mycotoxins On Livestock

Mycotoxins can have significant negative effects on the health, productivity and profitability of livestock. There are several points to consider when dealing with mycotoxins.

- Mold and mycotoxins reduce the nutritive value and palatability of feeds. Also, mold growth is often accompanied by high levels of yeast growth, both of which reduce nutrient quality and values (protein and energy) of a feed.

- Mycotoxins (deoxynivalenol (DON) or vomitoxin) reduce the animal’s ability to utilize fats, carbohydrates, proteins, macro-minerals, trace minerals and vitamins in the diet.

- Mycotoxins (DON, afaltoxin, ochratoxin and fumonisin) damage vital organ tissue such as the rumen lining, intestinal tissue, kidney and liver tissue. These mycotoxins will damage the DNA of the liver cells, which can significantly reduce the animal’s ability to process and utilize the nutrition of the diet. Mycotoxins can also predispose cows to a higher risk of metabolic conditions such as ketosis.

- Mycotoxins (zearalenone) compromise reproductive function. Many molds and mycotoxins are estrogenic and can disrupt normal ovary function.

- Mycotoxins in general are known to suppress immune function, which can reduce the animal’s resistance to disease and compromise the animal’s ability to properly respond to vaccination programs.

- Mycotoxins (ochratoxin) are carcinogenic and can seriously affect poultry health and production, especially in layers and broilers.

Monitoring For Symptoms Of Mycotoxin Exposure In A Dairy Herd

Through my years of working as a livestock nutritionist, I have learned that there are some situations that would indicate the need for an immediate investigation into the possibility of a mycotoxin exposure. For example:

1) Milk Production Drop: A significant drop in production (3 to 20 lbs./hd/day) in a relatively short time (1 to 14 days). This drop may happen in conjunction with feeding a new forage or grain. However, there can be pockets of mold growth/mycotoxins within a bunker, pile or silo which can unexpectedly cause a major drop in production without a change in feedstuffs.

2) High Intake Of Free Choice Mineral Or Salt: I recommend that cows should always have free choice mineral available (a complete mineral blend, that does not contain salt or any flavoring agents, offered next to a bin of free choice loose salt). Even when the ration is balanced and all of the mineral requirements are hopefully met in the TMR or ration, it is important to offer free choice mineral and free choice loose salt. The intent is to have the free choice mineral available as a safety net for cows that may need a little extra and to act as an indicator (a canary in the mine so to speak) of a possible problem with mineral utilization, or with the ration utilization in general. I have found many times that if the cows suddenly go from very little free choice mineral intake to a significant free choice mineral (or salt) intake, that mycotoxins have become a problem in the ration and a mycotoxin binder strategy should be implemented. The value of using free choice mineral as an early alert tool is only valid if a baseline of free choice mineral intake has been established for the cows prior to the intake spike.

3) Abnormal Dry Matter Intakes: Some mycotoxins are well known for reducing dry matter intake (DMI) in dairy cows. For instance, vomitoxin can significantly reduce DMI in lactating and dry cows. However, I have also experienced situations where mycotoxins caused dry cows to have abnormally high DMI as well. For example, Holstein far-off dry cows normally have a daily DMI of approximately 30 lbs. In one of these incidences, the dry cows DMI increased to 40 lbs. or more. When a good mycotoxin binder was added to the dry cow ration the DMI promptly went back to normal levels.

Is There Merit In Testing Feedstuffs For Mycotoxins?

As the awareness of mycotoxins in livestock feeds increases, the willingness to test feedstuffs for mycotoxins is also increasing. Testing individual feedstuffs, or the overall TMR can be a helpful tool in determining mycotoxin exposure to livestock. However, it is important to be aware there are some significant limitations to the amount and value of information provided by many of the current mycotoxin testing labs that prevent them from being the absolute determination of a mycotoxin problem in the feeds. Consequently, a lab analysis for mycotoxins should only be one part of an overall checklist to determine the degree of mycotoxin exposure to the livestock and the need for a plan of action. Here are some points to consider when assessing the value of a lab analysis for planning a strategy to address a suspected mycotoxin issue.

- There are over 300 molds that produce mycotoxins and typically most lab analysis only analyze for 4 or 5 mycotoxins.

- The sensitivity of a typical mycotoxin analysis in the industry is limited. When most test results state ‘none detected’ a question should remain. Mycotoxins are known to attach to other nutrients such as carbohydrates and can become masked from detection by standard laboratory analysis (Lateral Flow, ELISA, HPLC and TLC). As long as the mycotoxin is masked by the carbohydrate it is still a problem to the animal. However, the analysis may not be able to detect it properly. There is a lab analysis called LC-MS-MS that separates/unmasks the mycotoxin from the carbohydrate matrix for a higher sensitivity and more accurate test result on mycotoxins but not all labs are doing this type of analysis. When the mycotoxin is not separated from the carbohydrate, the standard deviation, or rate of error in detection for the test may be very high. These lower sensitivity analysis’ may report back “none-detected” on the whole report and yet there still could be a significant mycotoxin challenge to the livestock.

Assessing Tolerance Levels Of Mycotoxins

When considering the published industry standards for the tolerance level of each individual mycotoxin, keep in mind that the tolerance level is determined in an isolated setting with no other mycotoxin influence. There is the issue of synergy (two together act worse than the sum of each individual) between mycotoxins that comes into play and needs to be understood when assessing risk and strategy development. For example, if the animal is exposed to just one mycotoxin and the level in the ration is below an industry accepted tolerance level, then the impact on health and production may be low. This situation would not require a mycotoxin binder in the ration. However, a significantly different situation occurs if there are two mycotoxins in the ration. Even if both mycotoxins are well below their individual tolerance level, two mycotoxins can act synergistically and the impact on the animal can be as negative, or worse, than having one mycotoxin well over the tolerance threshold. Having more than two mycotoxins in the ration (even if below tolerance levels) presents an even higher risk.

What this means is that it is possible to have a lab analysis report for five mycotoxins, that found a detectable level of two mycotoxins, both below tolerance level and still have the cows demonstrate serious health and production problems due to mycotoxin exposure. It is also possible to have a lab analysis report that no mycotoxins were detected and there can still be a significant challenge to the animals from mycotoxins that were not detected or not analyzed for. That is why it is important to consider the lab analysis for mycotoxins in context with other herd production and health observations when determining a mycotoxin risk assessment and action plan.

What Is A Good Mycotoxin Binder Strategy?

Develop a mycotoxin assessment checklist for your herd incorporating the points outlined in this article. Assess the risk factor of new feedstuffs to be fed based on cropping and storage conditions. For example, if the corn silage dry matter is high (45% or higher) then the risk of poor fermentation is also high and conditions for mold growth mycotoxins are likely. If the affected feedstuff cannot be reduced or eliminated from the ration, then an effective mycotoxin binder should be fed.

Crystal Creek® Fuse 207™: Fuse 207 has both yeast cell wall glucans and polarized clays that have been shown to provide effective mycotoxin binding for a wide range of mycotoxins that are prevalent in the livestock industry such as aflatoxin, zearalenone, fumonisin, T2 and ochratoxin.

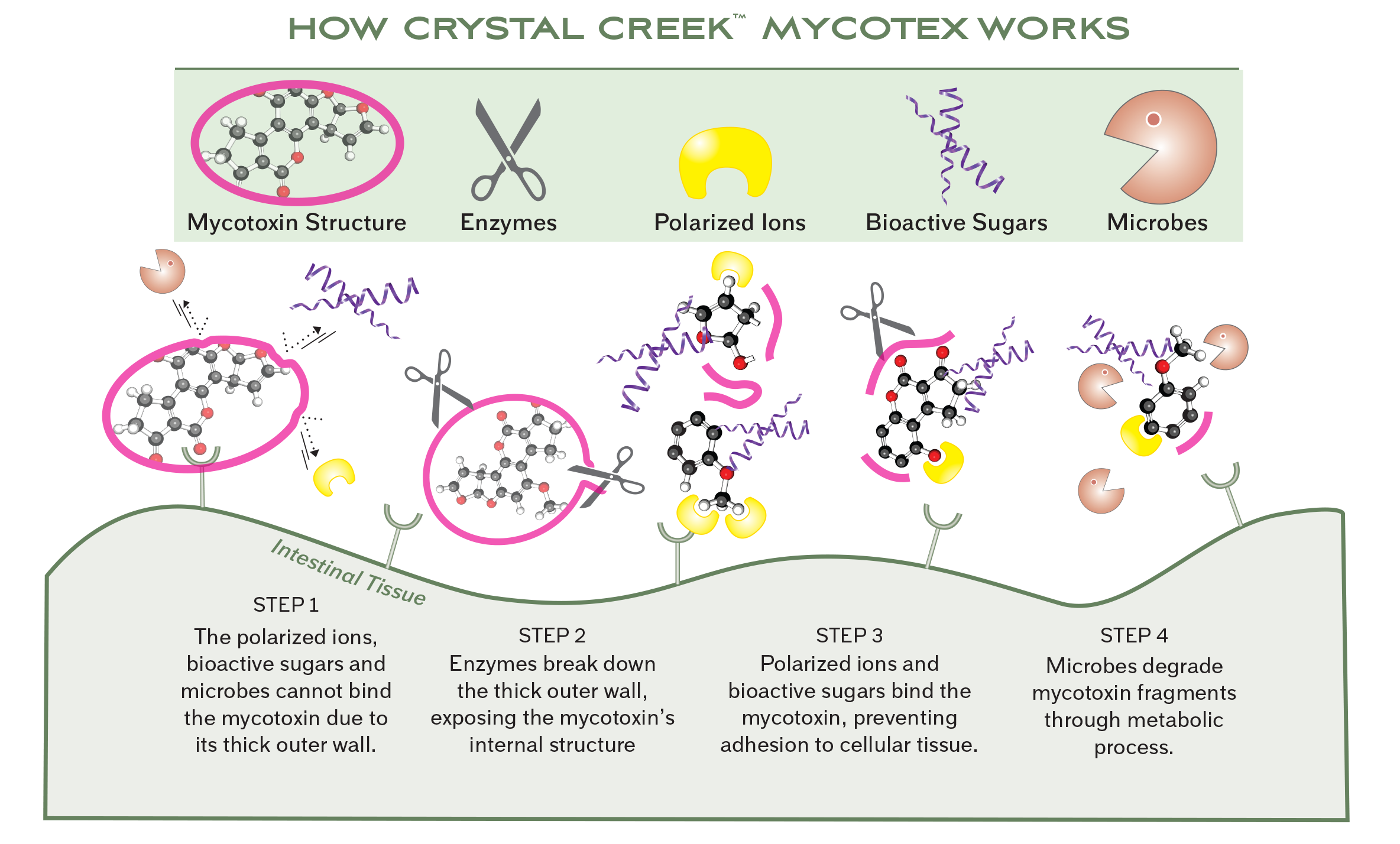

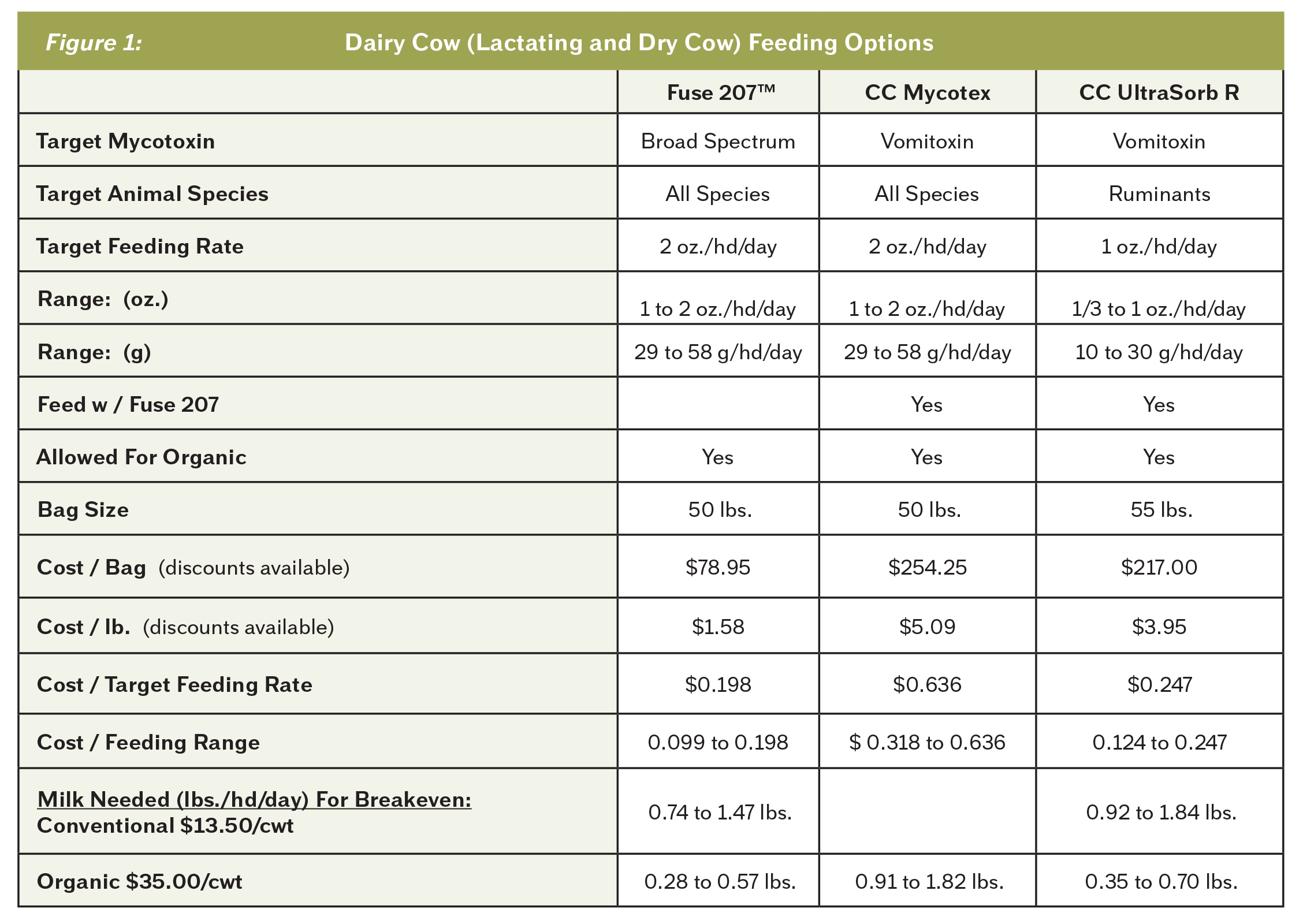

Dealing With Vomitoxin Needs A Two Step Strategy: Vomitoxin, in its unaltered state, cannot be bound by any mycotoxin binder. Vomitoxin needs to be reconfigured (opened up to expose attachment sites) in order for mycotoxin binders to effectively bind up vomitoxin. That is why Crystal Creek® offers a strategy for dealing with vomitoxin, using either Crystal Creek® Mycotex or UltraSorb R in conjunction with Fuse 207 (see Figure 1).

Crystal Creek® Mycotex: Provides enzymes specific to opening up the vomitoxin molecule so that it can be bound by the Fuse 207™. Crystal Creek® Mycotex is allowed for use in organic herds. Crystal Creek® Mycotex can be used in all species including ruminant, swine and poultry.

Crystal Creek® UltraSorb R: Provides a specific blend of enzymes designed to reconfigure the vomitoxin molecule so that the Fuse 207™ can properly bind with the vomitoxin. Crystal Creek® UltraSorb R is designed specifically for use in ruminant animals and is allowed for organic use. There is an UltraSorb P and an UltraSorb S available that are designed specifically to function in the unique digestive conditions of poultry and swine respectively when dealing with vomitoxin in these species.

Length Of Exposure To Mycotoxins Can Impact Strategy And Response

It is important to understand that the longer animals have been exposed to mycotoxins without the benefit of an effective mycotoxin binder in the ration, the more potential there is for damage to vital organs such as the digestive tract, kidneys, liver and immune system. If a new feedstuff is introduced to the ration, the cows drop significantly in production due to mycotoxins, and the animals are fed an effective mycotoxin binder within a couple of days, the animals many times will recover much of the lost production in a short time. However, if the animals are exposed to the mycotoxins for a longer period of time (two weeks or more) then the risk of organ damage is higher and the recovery will be slower relative to the length of time the animals have been exposed to mycotoxins.

It is also important to note that when vital organs are overexposed to mycotoxins, production may not return to normal even when an effective mycotoxin binder is put into the ration. It is possible to have some indicators, such as DMI, return to normal and still have production lag. At that point, the cows need to remain on the mycotoxin binding strategy. A short-term ration adjustment of 3 to 7 days for the whole herd (or especially for cows under 150 days in milk) may be required to kick-start a production recovery. In these situations it is recommended that you call your Crystal Creek® nutritionist and discuss which short-term ration strategy options would be best for your herd.

Feedstuffs containing mycotoxins are a fact of life that should not be ignored. They can be managed effectively with a proper strategy. Crystal Creek® partners with some of the most innovative companies in the mycotoxin binder industry and is able to take advantage of their technical expertise to bring advanced, effective products to our clients. Take advantage of the technical innovations and experience that Crystal Creek® offers to protect your bottom-line.