Ventilating Repurposed Structures For Calf Housing

Click here to view as a pdf: Ventilating Repurposed Structures For Calf Housing

By Alex Austin

By Alex Austin

Building a new calf raising facility is an expensive investment and not always an option. Converting an existing structure, whether it’s a pole shed or old stanchion barn, to house and raise calves can be a great option when done correctly. When considering repurposing an existing structure, a lot of thought goes into the logistics of everyday calf care, such as feeding and bedding, but one area that can be overlooked is proper ventilation. A poorly ventilated calf barn will quickly lead to struggles with calf health and poor performance. To avoid these and achieve proper ventilation, a system that can deliver fresh air in different penning set ups and overcome potential structural challenges is key.

Penning and Ventilation

One of the first things to decide when repurposing a structure is the penning and pen layout. This has a big impact on the ventilation design of the calf barn. Pairing calves or raising them in small groups of six or less can be a great option, if these groups or pairs have solid dividers. Mesh dividers, such as hog panels, can allow contagious pathogens to easily spread throughout the barn, resulting in poor calf health that is difficult to overcome. There should also be a less than one week age gap between calves in these pairs or groups. Recent research has shown benefits such as social development and increased feed intake resulting in improved average daily gains when calves are paired together. There have also been studies that have determined there is no increased risk for pathogen spreading in paired calf housing. Whether calves are in individual pens or in groups, the Crystal Creek® FLAP DUCT® can be custom designed to deliver fresh air to the calf area, no matter the layout.

Overcoming Structural Challenges

Many repurposed structures can come with some challenges for installing a FLAP DUCT® ventilation system. Sliding doors, solid walls and beams are just a few examples of some challenges that an existing structure can have.

Intake Fan

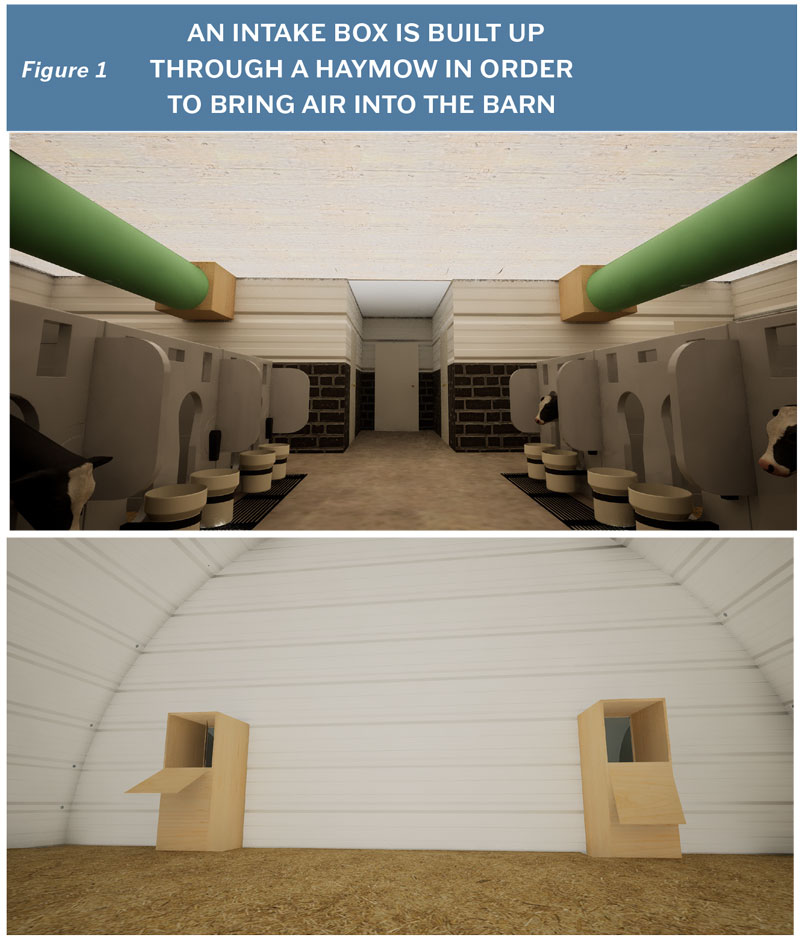

When it comes to bringing fresh air into the barn, the intake fan must be connected directly to the FLAP DUCT®. The place where the fan draws fresh air from can be flexible. To get around structural challenges, such as sliding doors or solid walls, intake boxes can be built to bring fresh outside air to the intake fan and into the barn. (See Figure 1)

Tube Placement

Ideally, tubes are placed directly over the top of calf pens, eight feet off the ground. This will achieve the best air flow into pens. Since this is not always an option, FLAP DUCT® ventilation tubes can be designed to throw air to the left and right, directing air into the pens. Hole sizing can also be adjusted in order to achieve the correct air speed at the calf level.

Exhaust Fans

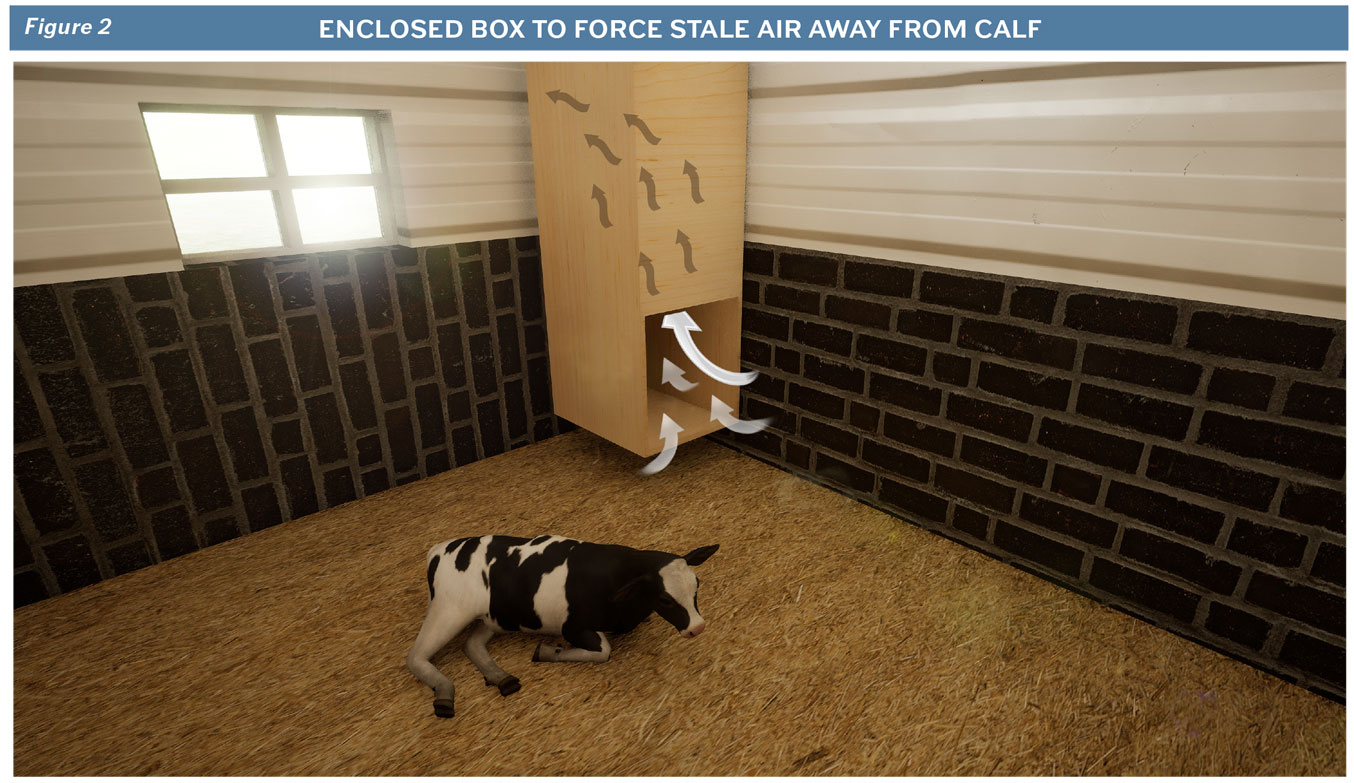

To assist with the removal of contaminated air from the calf space, exhaust fans are often used. The calf space is the immediate area where the calf lives, four feet off the ground in the calf pen. Exhaust fans that are mounted high off the ground do little to remove the low hanging contaminated air. To draw from the calf space, building an enclosed box down from the exhaust fan to the height of three feet off the ground (see Figure 2 ) will help to achieve this. This will force stale air to be removed from the calf level more effectively.

Ventilation Goals

The goal of a properly designed ventilation system is to provide clean, fresh air to the calf. By doing so, a ventilation system will also remove air borne pathogens, accumulated heat and moisture, as well as noxious gases from the calf space. Year-round ventilation is required to achieve this.

When designing a FLAP DUCT® ventilation system, three basic goals are met to ensure the best air quality possible for calves:

- Correct volume of fresh air delivered to the calf.

- Appropriate speed of the air on the calf based on temperature.

- Adequate distribution of fresh air in the calf space.

Volume

The amount of air being drawn into a barn by a ventilation system is called the volume. According to the University of Wisconsin School of Veterinary Medicine, properly ventilated calf barns should experience a minimum of four air exchanges per hour in the winter. Practical experience by the ventilation team at Crystal Creek® has shown that ventilation rates can and should exceed four air exchanges per hour in the winter.

Speed

The air speed is measured at the calf level. This is the speed at approximately four feet off the ground. During cold weather, calves should not experience a draft, defined as air speeds greater than 60 feet per minute. Summertime air speeds should have a goal of 200 feet per minute or greater for heat abatement and fly pressure relief.

Distribution

The distribution of air describes where the fresh air is going in the barn. The goal of any ventilation system should be to distribute fresh air to the calf space. The calf space is the penning where the calf lives plus four feet off the ground. When it comes to proper air distribution, the distance and position of the tubes are very important. Ideally, tubes should be placed directly above the calf. If this is not an option, hole placement should be designed to throw air left and/or right into the calf space. Preferably, tubes should be placed at eight feet from the bottom of the tube to the ground, but no higher than ten feet.

When it comes to housing calves, producers should not overlook old barns or pole sheds they already have. An existing structure can be successfully repurposed into a calf raising facility. A well-designed ventilation system, such as the FLAP DUCT®, is key to that success. The ventilation specialists at Crystal Creek® have the experience and knowledge to overcome structural challenges and design an effective ventilation system that delivers excellent air quality to calves. To learn more about the FLAP DUCT® calf barn ventilation system, visit www.crystalcreeknatural.com.

References available upon request.